Ipuleti le-Tungsten yethusi lesikebhe lifa izingxenye ezingezona ezijwayelekile

Incazelo yomkhiqizo

| Umkhiqizo | i-tungsten yethusi ingxubevange |

| Okubalulekile | W+Copper+Ni |

| Ibanga | W+Copper+Ni |

| Usayizi Wokusanhlamvu | kuhle, okuphakathi |

| Ukuqina | 87.6-94HRA |

| T.R.S | 3000-4200 |

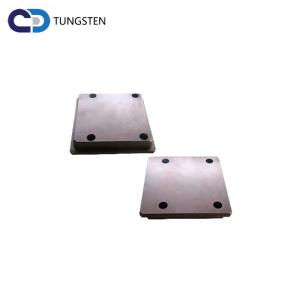

| Ubuso | kungenalutho noma umhlabathi |

| Isicelo | isivalo esivaliwe se-transistors sealing welder, izinto zokuthintana zokushintshwa kwe-highvoltage nama-electrode okucubungula inhlansi njll. |

Izinhlobo, ukwakheka kwamakhemikhali kanye nezakhiwo eziyinhloko:

Uhlobo | ukwakheka kwamakhemikhali e-copper tungsten alloy (%) | ukumelana(cm) | amandla okubamba (kg/mm2) | ubulukhuni | density(g/cm3) |

W | Cu |

CD1-3 | 60 | ibhalansi | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Ibhrendi kanye NO. | Izingxenye zamakhemikhali% | Izici ezingokomzimba |

Cu | Ukungcola okuphelele ≤ | W | Ukuminyana (g/cm³) ≥ | Ukuqina HB ≥ | Ukungazweli (µΩ·cm) ≤ | I-Conductivity IACS%≥ | Amandla okugoba I-Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | U-Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | U-Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | U-Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | U-Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | U-Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Isici somkhiqizo :

1.Ukumelana nokushisa okungcono

2.I-ablate-resistance engcono

3.Ukuminyana okuphezulu

4.Amandla aphezulu

5.I-conductivity enhle kakhulu ye-thermal ne-elctrical

6.Kulula ukwenziwa ngomshini

Zonke izinto zethu zokwakha zikhiqizwa abezindaba, i-sinter, kanyeinqubo yokungena. Ukukhiqiza ngakunyeisinyathelo, okuhlanganisa impushana eyisisekelo, silawulwa eduze, siqashwe, futhi sisayinwe yi-Quality Assurance. Ngemva kokuqedwa, zonke izinkatho ezikhiqiziwe zibhekwa ukuthi azikho yini izinto, ukuminyana, nobulukhuni ngaphambi kokuthunyelwa. Lolu lwazi luyarekhodwa futhi lugcinwe efayelini, futhi luhambisana nezingxenye noma izinto zokwakha lapho zicelwa.

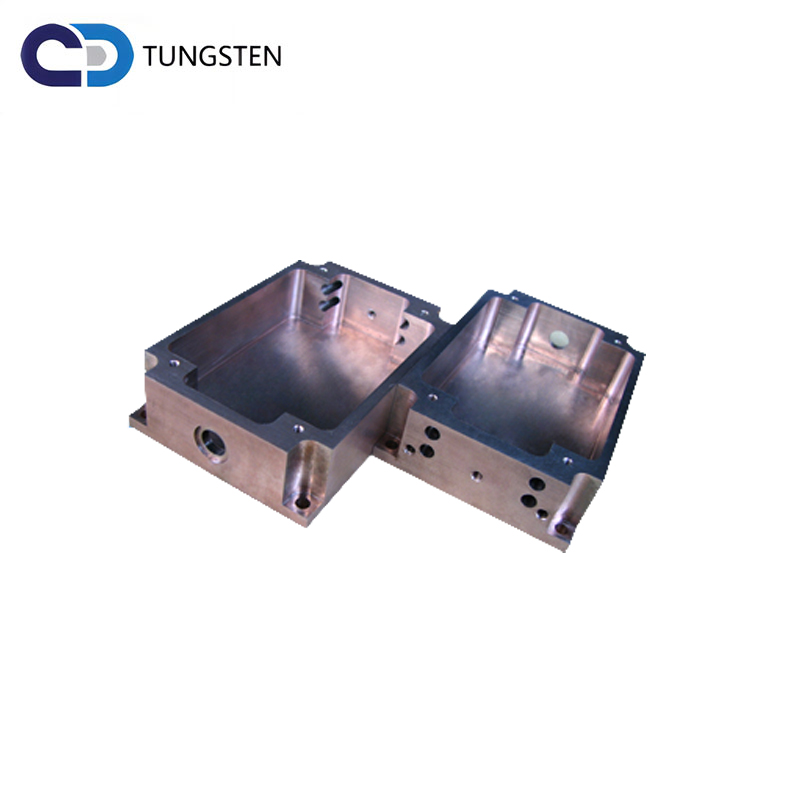

I-EDM ne-ECM

izinhlanganisela ze-tungsten zisetshenziswa emhlabeni wonke kuma-electrode e-EDM (Electrical Discharge Machining) kanye ne-ECM (Electrochemical Machining). Zonke izinto ezisetshenziswayo zenziwa umshini wokunyathelisa, i-sinter, kanye nenqubo yokungena. Kusetshenziswa izimpushana ze-Virgin, okuholela ekutheni kube ne-homogeneous material engaguquki enikeza amanani aphezulu ngisho nokushiswa. I-tungsten yethusi isetshenziswa ezinhlelweni ze-plunger/sinker lapho kudingeka khona incazelo eyinkimbinkimbi, ikakhulukazi ku-tungsten carbide.

Ubukhulu

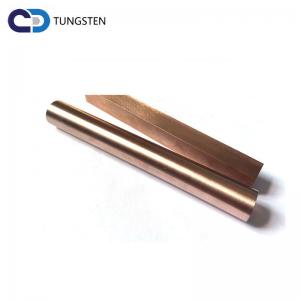

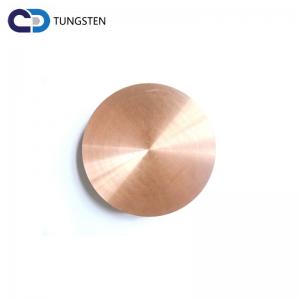

Amabhola: φ 1.5mm -φ 100mm

Amashafu: (φ1mm ngaphezulu)× (Ubude max.600mm)

AmaSpredishithi: (Ubukhulu 0.15mm ngaphezulu)×(Ububanzi max.200mm)×(Ubude max.500mm)

Osayizi abayisikwele, abayindilinga nonxande: ububanzi bungama-550mm ngaphezulu

Ngokusho kwabafunayo

Kungani Usikhethe:

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

Isibonisi sasefekthri

XHUMANA NATHI

info@zztungsten.com