Ipleyiti yobhedu yeTungsten ifa non standard parts

Ingcaciso yeMveliso

| Imveliso | ingxubevange yobhedu tungsten |

| Izinto eziphathekayo | W+Copper+Ni |

| IBanga | W+Copper+Ni |

| Ubungakanani benkozo | kulungile, phakathi |

| Ukuqina | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Umphezulu | ingenanto okanye umhlaba |

| Isicelo | ikepusi etywiniweyo ye-transistors yokutywina i-welder, izixhobo zonxibelelwano zokutshintsha kwe-highvoltage kunye nee-electrode zokusetyenzwa kwentlantsi njl. |

Iintlobo, ukwakheka kweekhemikhali kunye neempawu eziphambili:

Uhlobo | Ukwakhiwa kweekhemikhali zobhedu lwe-tungsten alloy (%) | ukumelana (cm) | amandla okuqina (kg/mm2) | ubulukhuni | density(g/cm3) |

W | Cu |

CD1-3 | 60 | ibhalansi | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Uphawu kunye NO. | Amalungu emichiza% | Iimpawu ezibonakalayo |

Cu | Ukungcola okupheleleyo ≤ | W | Ukuxinana (g/cm³) ≥ | Ukuqina HB ≥ | Ukuxhathisa (µΩ·cm) ≤ | Ukuqhuba IACS%≥ | Ukugoba amandla Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | UBhal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | UBhal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | UBhal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | UBhal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | UBhal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Uphawu lweMveliso :

1.Ukumelana nobushushu obungcono

2.Ngcono ablate-resistance

3.Ukuxinana okuphezulu

4.Ukuqina okuphezulu

5.Ukuqhuba kakuhle kwe-thermal kunye ne-elctrical

6.Kulula ukwenziwa ngoomatshini

Zonke izixhobo zethu ziveliswa ngumshicileli, i-sinter, kunyeinkqubo yokungena. Imveliso nganyeinyathelo, kubandakanywa umgubo osisiseko, ulawulwa ngokusondeleyo, ubekwe iliso, kwaye usayinwe yi-Quality Assurance. Emva kokugqitywa, zonke iiqashiso ezenziweyo zijongwa ukuba ziqhube njani, ukuxinana, kunye nokuqina phambi kokuthunyelwa. Le ngcaciso irekhodwa kwaye igcinwe efayilini, kwaye ikwakhapha iinxalenye okanye imathiriyeli xa iceliwe.

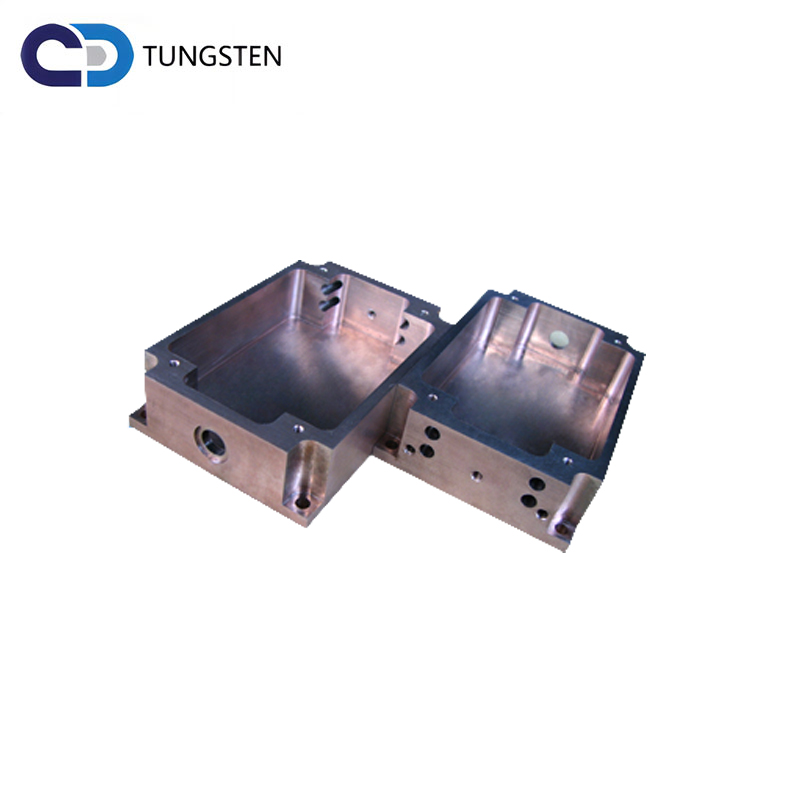

I-EDM kunye ne-ECM

i-tungsten composites isetyenziswe kwihlabathi jikelele kwi-EDM (i-Electrical Discharge Machining) kunye ne-ECM (i-Electrochemical Machining) i-electrodes. Yonke imathiriyeli yenziwa ngoshicilelo, i-sinter, kunye nenkqubo yokungena. Umgubo weVirgin uyasetyenziswa, okukhokelela kwisixhobo esingaguqukiyo esinika amazinga aphezulu kunye nokutshisa. I-tungsten yobhedu isetyenziswe kwi-plunger / sinker izicelo apho kufuneka inkcazo eyinkimbinkimbi, ngakumbi kwi-tungsten carbide.

Imilinganiselo

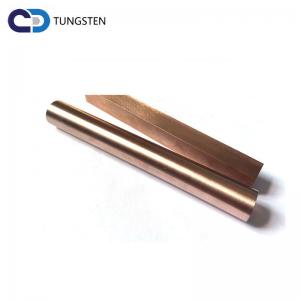

Iibhola: φ 1.5mm -φ 100mm

Iishafu: (φ1mm ngaphezulu)×(Ubude max.600mm)

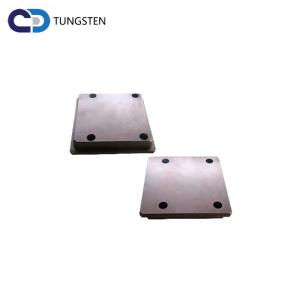

Amaxwebhu: (Ukutyeba 0.15mm ngaphezulu)×(Ubukhulu max.200mm)×(Ubude max.500mm)

Isikwere, ubungakanani obungqukuva kunye noxande: ubukhulu be-550mm ngaphezulu

Ngokwemfuno

Kutheni Ukhetha Thina:

1. Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

2. Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhanjiswa kwendlu ukuya emnyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

3. Izinto esizibonelelayo zingqinisiseka ngokupheleleyo, ukusuka kwisatifikethi sovavanyo lwemathiriyeli ekrwada ukuya kwisiteyitimenti somgangatho wokugqibela.(Iingxelo ziya kubonisa ngokwemfuneko)

4. isiqinisekiso sokunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

5. Unokufumana ezinye iindlela zesitokhwe, ukuhanjiswa kwelitye kunye nokunciphisa ixesha lokuvelisa.

6. Sizinikezele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

Umboniso wasefektri

QHAGAMSHELANA NATHI

info@zztungsten.com