Ngophuhliso oluqhubekayo lweteknoloji yezoshishino, izinto ezintsha kunye neenkqubo ezintsha ziqhubeka zivela.IiBha zokubhangisa,njengesixhobo soqhagamshelwano esibalulekileyo, nazo zisoloko ziphuculwa kwaye zihlaziywa ukuze zihlangabezane neemfuno zemathiriyeli emitsha kunye neenkqubo ezintsha. Ngokomzekelo, ukuze uhlangabezane neemfuno zokukhanya kunye namandla aphezulu kwintsimi ye-aerospace, ii-Bucking Bars ezenziwe ngezinto eziphezulu zokusebenza ezifana ne-tungsten alloys ziye zaphuhliswa. Ukusetyenziswa kwezi zixhobo zitsha kukhuthaze uphuhliso lobuchwepheshe be-aerospace.

Yintoni iTungsten Bucking Bar?

Tungsten Bucukumkani bar sisixhobo somsebenzi esifunyenweyo emva kwemiphezulu yokusebenza ukunika ilungu elixhasayo ekusebenziseni izibophelelo zempembelelo kwaye kubandakanywa nentloko yesixhobo edibeneyo kunye neendawo zokuphatha kunye ne-spacer ephantsi-recoil impembelelo-efunxayo ebonelelwe apho i-betwe.en ukuthatha imithwalo yokothuka kuxinzelelo kunye nokucheba.

IiBha zokubhaqa zineenzuzo ezilandelayo xa kuthelekiswa nezinye izixhobo zoqhagamshelo

Izinto eziluncedo:

1. Amandla aphezulu oqhagamshelwano kunye nokuthembeka:

Ngethuba lenkqubo ye-riveting, i-Bucking Bars inikezela ngenkxaso ezinzileyo kunye neqinile emva kwe-rivet, enokuthi iguqule ngokuchanekileyo i-rivet kwaye yenze uxhumano oluqinileyo. Le ndlela yokudibanisa inokumelana nemithwalo emikhulu efana noxinzelelo, uxinzelelo kunye namandla okucheba. Xa kuthelekiswa noqhagamshelo lweglue okanye uqhagamshelo olulula lwe-ferrule, amandla okudibanisa kunye nokuthembeka kwayo kungcono, kwaye ifanelekile kwizakhiwo ezineemfuno zamandla aphezulu, ezifana ne-fselages yeenqwelo-moya, iibhulorho, izakhelo zokwakha, njl.

Ngaphantsi kokusetyenziswa kwexesha elide okanye iimeko ezinzima zokusebenza ezifana nokuguquguquka kunye nokutshintsha kwengcinezelo, isakhiwo esixhunywe yi-Bucking Bars sisenokugcina uzinzo oluhle kwaye alulungele ukukhulula okanye ukungaphumeleli koxhulumaniso.

Ukusetyenziswa ngokubanzi:

2. Ukulungelelaniswa kwezinto ezinamandla: IiBhasi zeBucking zezixhobo ezahlukeneyo zingakhethwa ngokweemfuno ezahlukeneyo zomsebenzi ukulungelelanisa i-riveting yezinto ezahlukeneyo.

3. Ifanelekile kwizakhiwo eziyinkimbinkimbi: Ubume bayo kunye nobukhulu bayo bunokuthi buyilwe kwaye bulungelelaniswe ngokweemeko ezithile zomsebenzi, kwaye zinokusebenza kwizakhiwo ezinemilo enzima kunye neendawo ezimxinwa, njengemibhobho egobileyo, i-cavities emxinwa, izakhiwo ezikhethekileyo, njl. ., ekunzima ukwenza ezinye izixhobo zoqhagamshelwano ezininzi.

4. Ukusebenza ngokulula: IiBha zokubhaqa zisetyenziswa ngokubambisana nezixhobo ezifana nemipu ye-rivet, kwaye inkqubo yokusebenza ilula.

Iimeko ezithile zokusetyenziswa kweeBhara zokuBucking kwiinkalo ezahlukeneyo

1. I-Aerospace

Indibano ye-Aircraft fuselage: Ngexesha lenkqubo yokwenziwa kweenqwelo-moya, inani elikhulu le-riveting liyafuneka phakathi kwesikhumba se-fuselage kunye nesakhelo. Ngokomzekelo, kwindibano ye-fuselage yeenqwelo-moya ezithwala abantu ezifana ne-Boeing 737 kunye ne-Airbus A320, ii-Bucking Bars zisetyenziselwa ukuqinisekisa ukuba i-rivets idibanisa ngokuqinileyo ulusu kunye nesakhelo.

Uqhagamshelwano lwecandelo le-injini: I-injini yenqwelomoya yeyona nto iphambili kwinqwelomoya, kwaye ezinye izinto ezinobushushu obuphezulu kunye nezakhiwo ezingaphakathi kuyo nazo kufuneka zidityaniswe ngokuqhuqha. Ngokomzekelo, ukudibanisa phakathi kwe-injini ye-injini kunye ne-hub yevili kunokugqithwa ngokuchanekileyo ngokusebenzisa i-Bucking Bars. Ukufakwa kwee-rivets kuvumela ukuba i-blade igxininiswe ngokuzinzileyo kwi-hub yevili.

2. Indawo yokwenziwa kweemoto

Indibano yesakhelo somzimba: Ekwenzeni iifreyimu zomzimba wemoto, amaphepha esinyithi eemilo ezahlukeneyo kunye nobukhulu kufuneka adityaniswe kunye. Ngokomzekelo, kwinkqubo yendibano yesakhelo somzimba wemoto, iiBhara zokuBucking zisetyenziselwa ukudibanisa amacandelo afana neeplanga zecala, iiplanga ezinqamlezayo kunye nophahla. Uqhagamshelo olukhutshiweyo lunokubonelela ngamandla awoneleyo okumelana ne-torsion kunye nempembelelo yempembelelo ngexesha lokuqhuba isithuthi. Ngexesha elifanayo, xa kuthelekiswa ne-welding, i-riveting inokunciphisa ukuguqulwa komzimba kunye nokuphucula ukuchaneka kwendibano yomzimba.

Ukufakwa kwesitulo semoto: I-Riveting idla ngokusetyenziselwa ukulungisa izihlalo zeemoto. I-Bucking Bars isetyenziselwa ukufakela i-rivets yokulungisa izihlalo ukwenzela ukuba izihlalo zikwazi ukumelana namandla angenayo okwenziwa ngokubhuqa ngokukhawuleza, ukujika okubukhali, njl., Ukuqinisekisa ukuba izihlalo aziyi kukhululeka.

3. Indawo yokwakha iinqanawa

Iqokobhe leHull lidibanisa: Ekwakhiweni kweenqanawa, igobolondo le-hull lidityaniswe ngamacwecwe amaninzi ensimbi. Ngokomzekelo, kwinkqubo yokwenziwa kweenqanawa ze-10,000 zeetoni zempahla, i-Bucking Bars isetyenziselwa ukudibanisa iziqwenga zeeplate zetsimbi ngokukhwela. Kuba iinqanawa zichatshazelwa zizinto ezahlukeneyo ezinje ngokutya kwamanzi olwandle, impembelelo yamaza kunye noxinzelelo lwempahla ngexesha lokuhamba, le ndlela yokuhambisa inokuqinisekisa ukutywinwa kunye namandla okwakhiwa kwe-hull kunye nokuthintela amanzi olwandle ukuba angangeni kwi-hull.

Ukwakhiwa kwesakhiwo sangaphakathi ngenqanawa: Ezinye ii-bulkheads zokwahlula kunye nezakhiwo zenkxaso yedekhi ngaphakathi kwenqanawa nazo zakhiwe ngokukhwela. I-Bucking Bars inokunceda ukugqiba ukufakwa kwee-rivets ekwakhiweni kwezi zakhiwo zangaphakathi eziyinkimbinkimbi, ukwenza ulwakhiwo lwangaphakathi lwenqanawa luqine kwaye luthembeke, lunikeze ukhuseleko lokuhamba ngokukhuselekileyo kwenqanawa kunye nokugcinwa kwempahla.

4. Indawo yokwakha

Uqhagamshelo lwesakhiwo sentsimbi: Kwizakhiwo zesakhiwo sensimbi, ezifana nokwakhiwa kwesakhelo se-gymnasiums enkulu, iihholo zemiboniso kunye nezinye izakhiwo, ii-Bucking Bars zisetyenziselwa ukudibanisa amacandelo ezakhiwo ezinjengeentsimbi zetsimbi kunye neentsika zetsimbi. Ngokomzekelo, ngexesha lokwakhiwa kwesakhelo sensimbi yeSitediyamu seSizwe "I-Bird's Nest", i-Bucking Bars yayisetyenziselwa ukudibanisa kwe-rivet. Le ndlela yokudibanisa inokuqinisekisa ukuzinza kunye nokukhuseleka kwezakhiwo zesakhiwo sensimbi phantsi kweemeko zobunzima bazo, imithwalo yomoya, amandla okuzamazama komhlaba, njl.

Ukufakwa kodonga lwamakhethini: Ukufakwa kweendonga zamakhethini wokwakha ngamanye amaxesha kwenziwa kwakhona nge-riveting. I-Bucking Bars inokunceda ukudibanisa ngokuqinileyo isakhelo sesinyithi okanye ipleyiti yodonga lomkhusane kwisakhiwo esiyintloko sesakhiwo, ukuqinisekisa ukuba udonga lomkhusane lunokuhlala luzinzile phantsi kweemeko zemozulu ezahlukeneyo (ezifana nemimoya enamandla, iimvula ezinkulu, njl.) itywinwe kakuhle ukuthintela ukungena kwemvula nomoya.

5. Indawo yokwenza izixhobo zombane

Indibano yeqokobhe leChassis: Ukwenziwa kwesixhobo sombane se-chassis, njenge-chassis ye-server, i-chassis yekhompyutheni, njl. Le chassis kufuneka iqinisekise ukusebenza kwe-electromagnetic shielding kunye namandla oomatshini. I-Riveting inokwenza iqokobhe liqhagamshelwe ngokuqinileyo ukuze lihlangabezane neemfuno zokhuselo lwe-electromagnetic, kwaye kwangaxeshanye likwazi ukumelana nongquzulwano oluthile kunye ne-extrusions ukukhusela izinto zangaphakathi ze-elektroniki.

Ukulungiswa kweradiator: I-radiator yezixhobo ze-elektroniki ngokuqhelekileyo kufuneka igxininiswe ngokuqinileyo kwi-chip okanye kwezinye izinto zokufudumeza. Kwezinye iiseva eziphezulu okanye iikhomputha zolawulo lwemizi-mveliso, ii-Bucking Bars zisetyenziselwa ukufakela i-rivet ukulungisa i-radiator ukuqinisekisa uqhagamshelwano oluhle phakathi kwe-radiator kunye ne-heater element, ngaloo ndlela ikhupha ngokufanelekileyo ubushushu kunye nokuthintela izixhobo ukuba zonakaliswe ngenxa yokushisa.

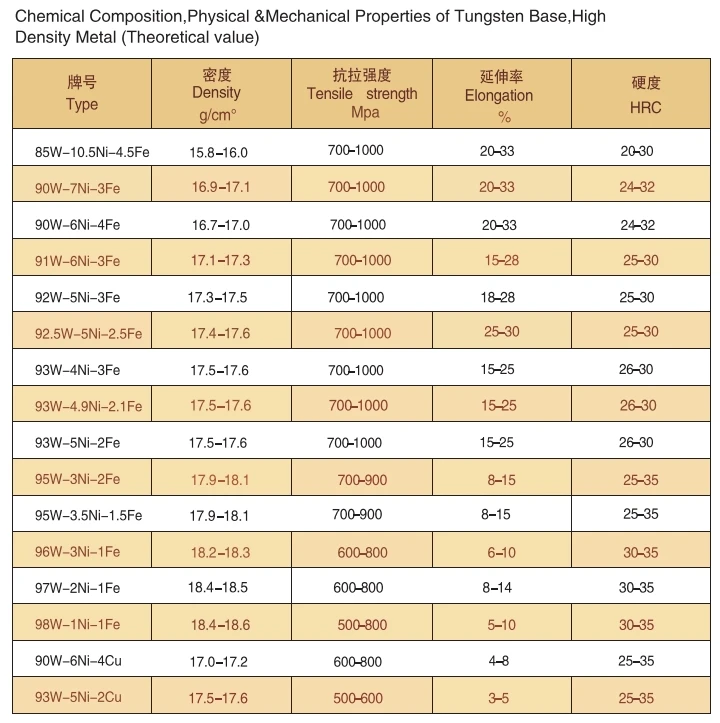

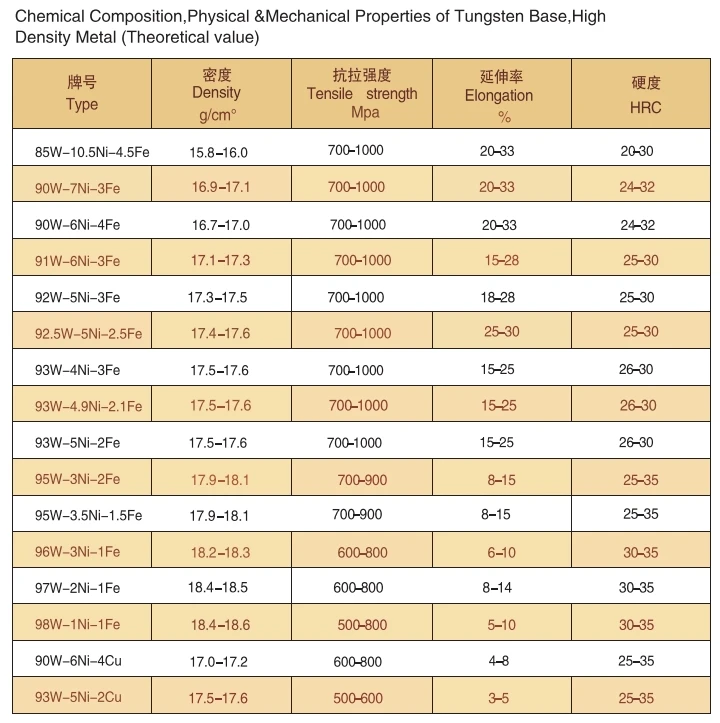

Isishwankathelo, i-WNiFe tungsten alloy bucking bar idlala indima yayo ekhethekileyo kwiinkalo ezininzi. Xa ukhetha ibha ye-bucking, kufuneka ukhethe ibakala elifanelekileyo lezinto eziphathekayo ngokweemfuno ezithile zokusetyenziswa kunye nendawo yokusebenza ukuqinisekisa ukusebenza kwayo kunye nobomi benkonzo.

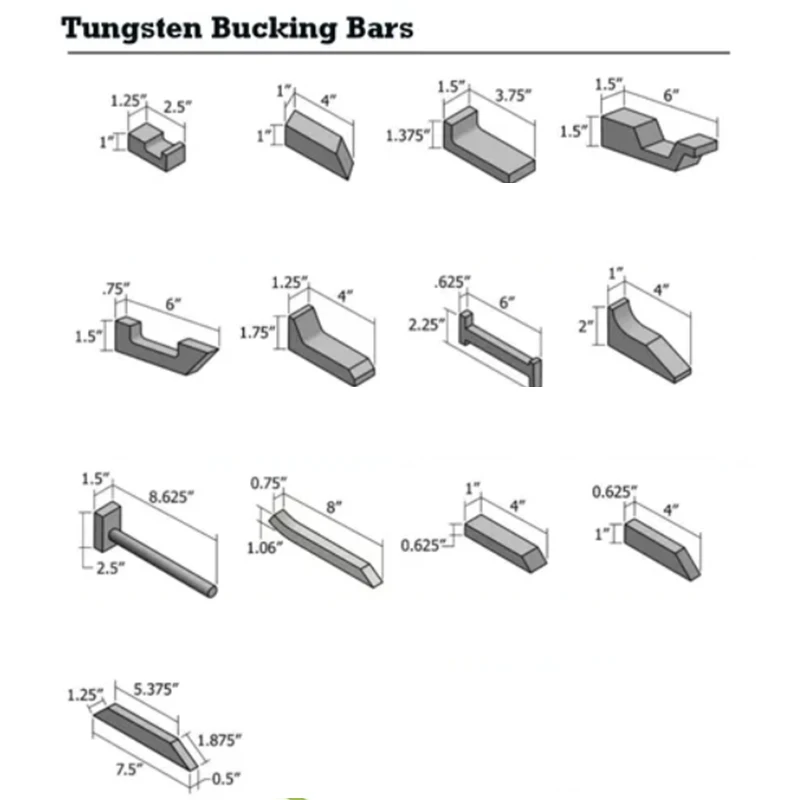

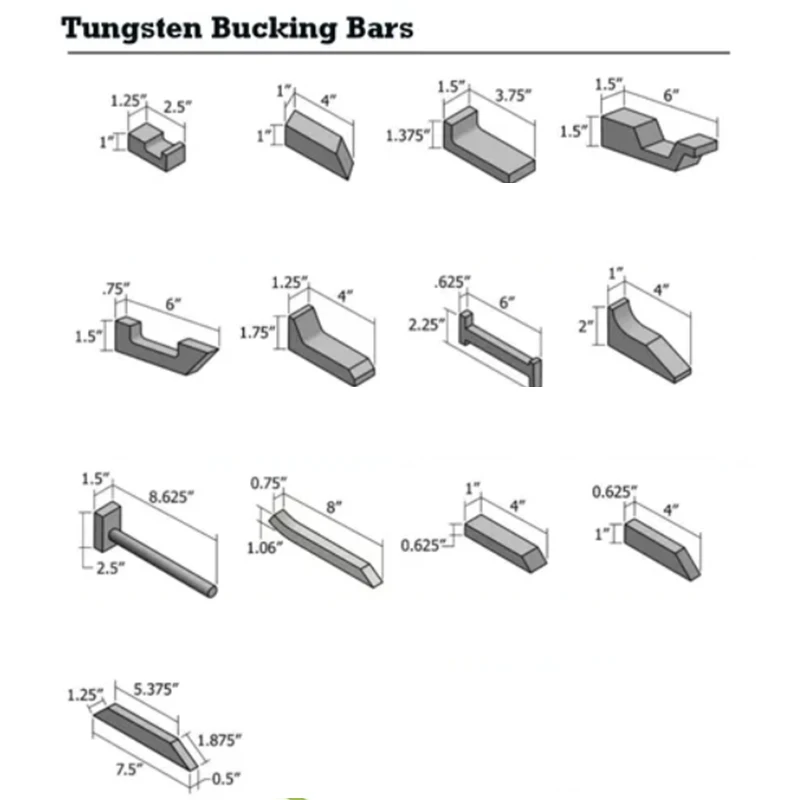

Imiboniso yethu yeProfuct