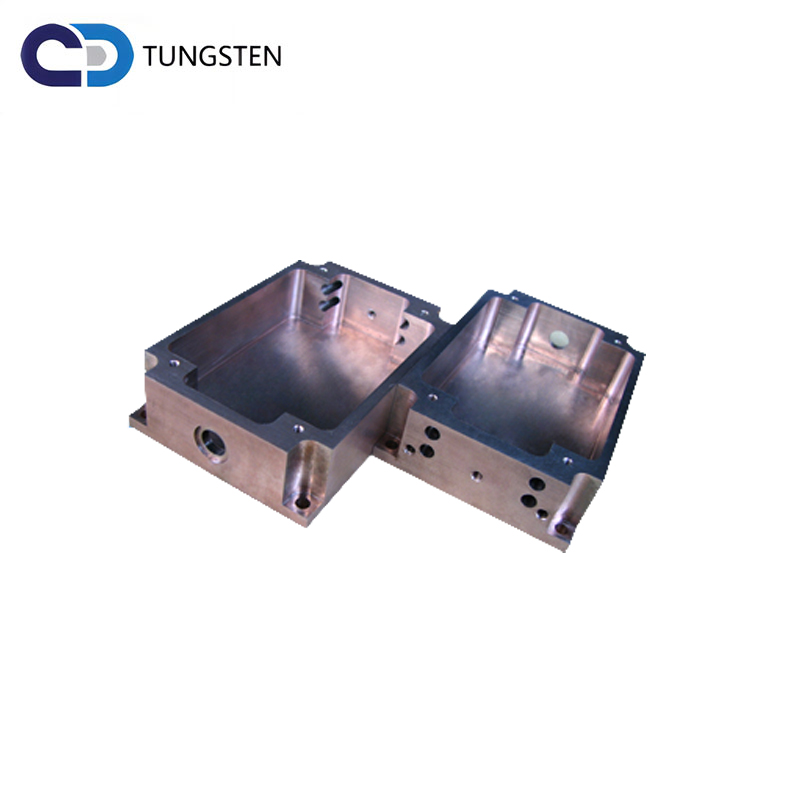

Tungsten copper boat plate die non standard parts

Product description

| Product | tungsten copper alloy |

| Material | W+Copper+Ni |

| Grade | W+Copper+Ni |

| Grain Size | fine, medium |

| Hardness | 87.6-94HRA |

| T.R.S | 3000-4200 |

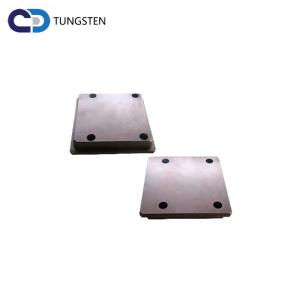

| Surface | blank or ground |

| Application | sealed cap for transistors sealing welder,contactor materials for highvoltage switches and electrodes for spark processing etc. |

Types,chemical compositions and main properties:

Type | chemical composition of copper tungsten alloy(%) | resistivity(cm) | tensile strength(kg/mm2) | hardness | density(g/cm3) |

W | Cu |

CD1-3 | 60 | balance | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Brand and NO. | Chemical components% | Physical properties |

Cu | Total impurities ≤ | W | Density (g/cm³) ≥ | Hardness HB ≥ | Resistivity (µΩ·cm) ≤ | Conductivity IACS%≥ | Bending strength Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Product feature :

1. Better heat resistance

2. Better ablate-resistance

3. High densisty

4. High intensity

5. Excellent thermal and elctrical conductivity

6. Easy to be machined

All of our materials are produced by the press, sinter, and infiltrate process. Each manufacturing step, including the basic powder, is closely controlled, monitored, and signed off on by Quality Assurance. After completion, all manufactured lots are checked for conductivity, density, and hardness prior to shipping. This information is recorded and kept on file, and also accompanies the parts or materials when requested.

EDM and ECM

tungsten composites are used worldwide for EDM (Electrical Discharge Machining) and ECM (Electrochemical Machining) electrodes. All material is manufactured by the press, sinter, and infiltrate process. Virgin powders are used, resulting in a consistent homogeneous material giving high and even burning rates. Copper tungsten is used in plunger/sinker applications where intricate definition is required, especially in tungsten carbide.

Dimensions

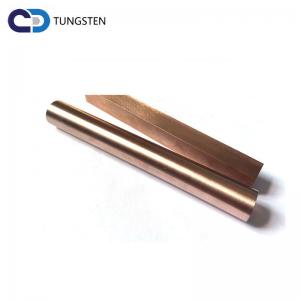

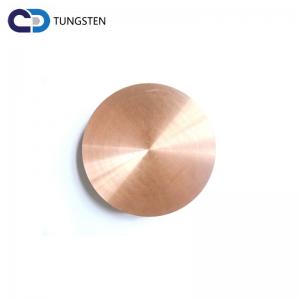

Balls: φ 1.5mm -φ 100mm

Shafts: (φ1mm above)×(Length max.600mm)

Sheets: (Thickness 0.15mm above)×(Wideness max.200mm)×(Length max.500mm)

Square, round and rectangle sizes: diameter 550mm above

According the demanding

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factory display

CONTACT US

info@zztungsten.com