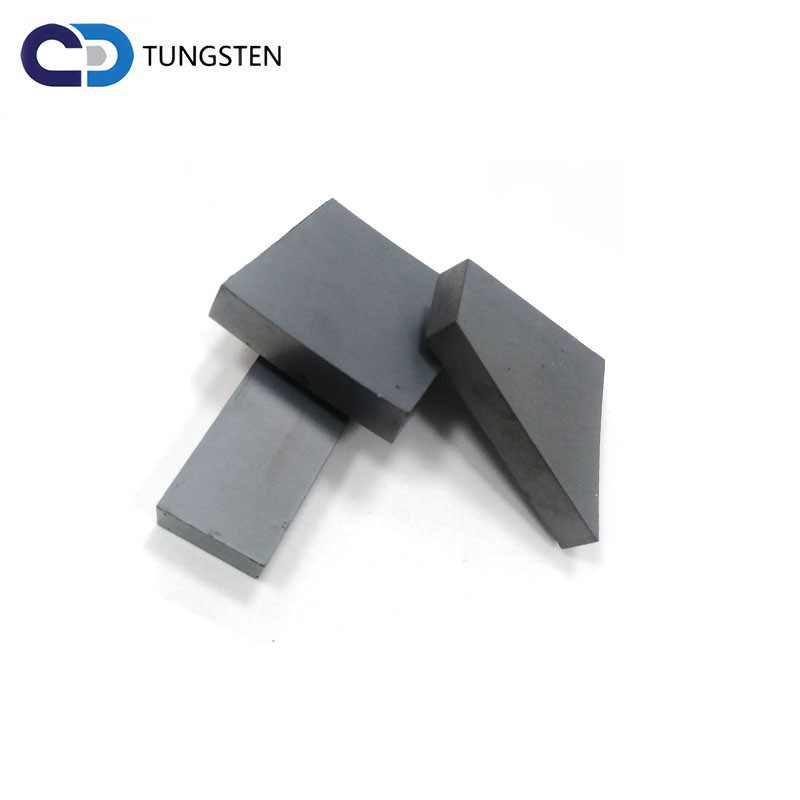

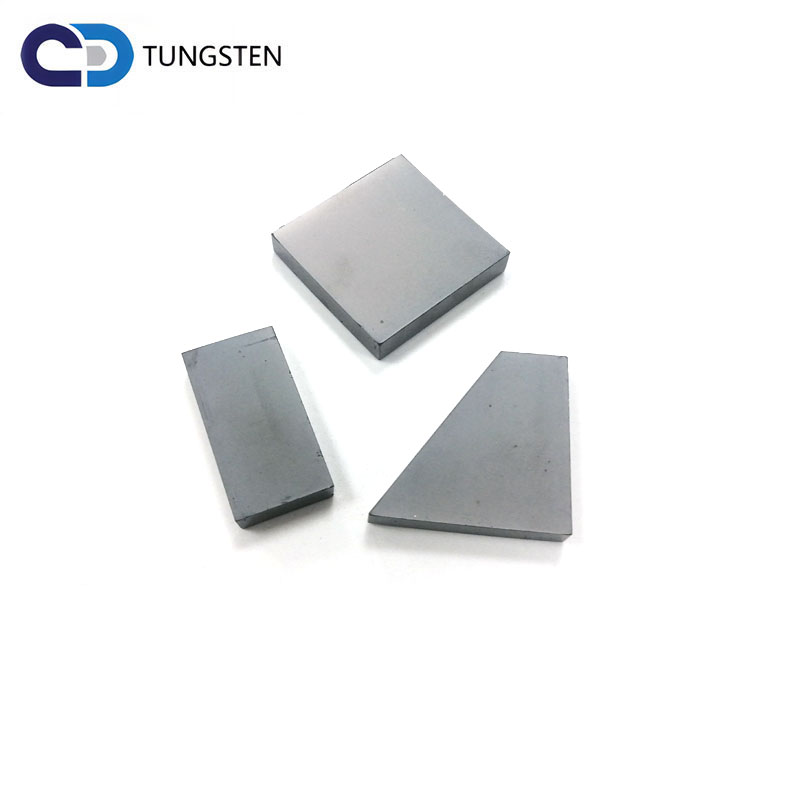

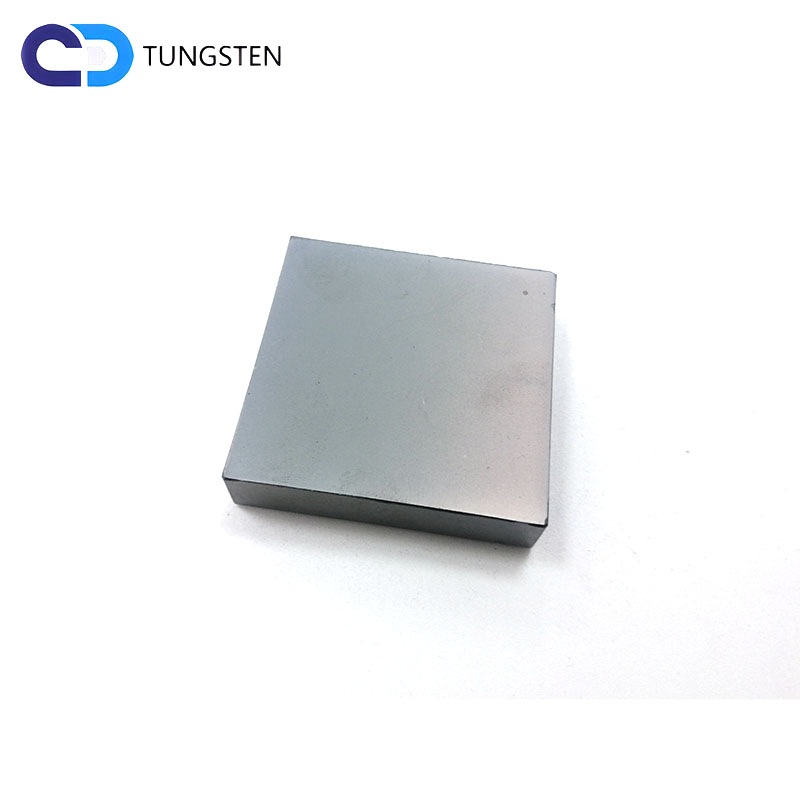

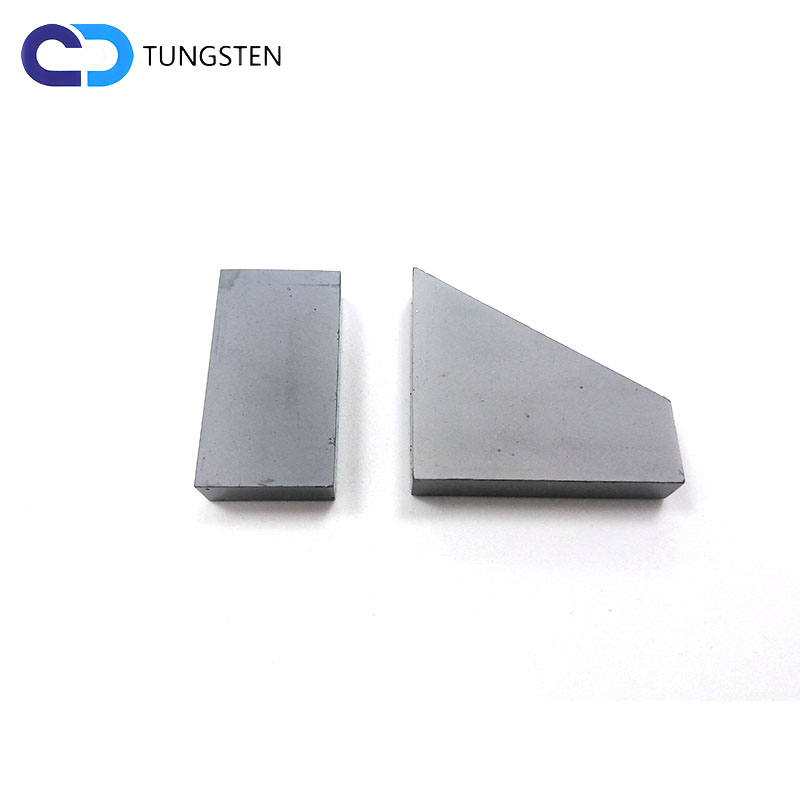

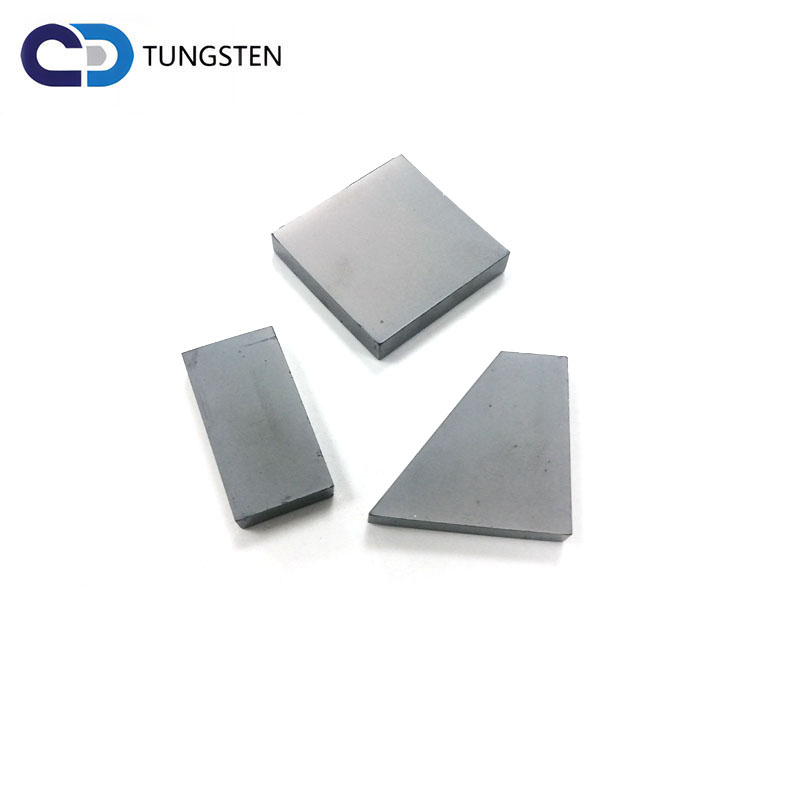

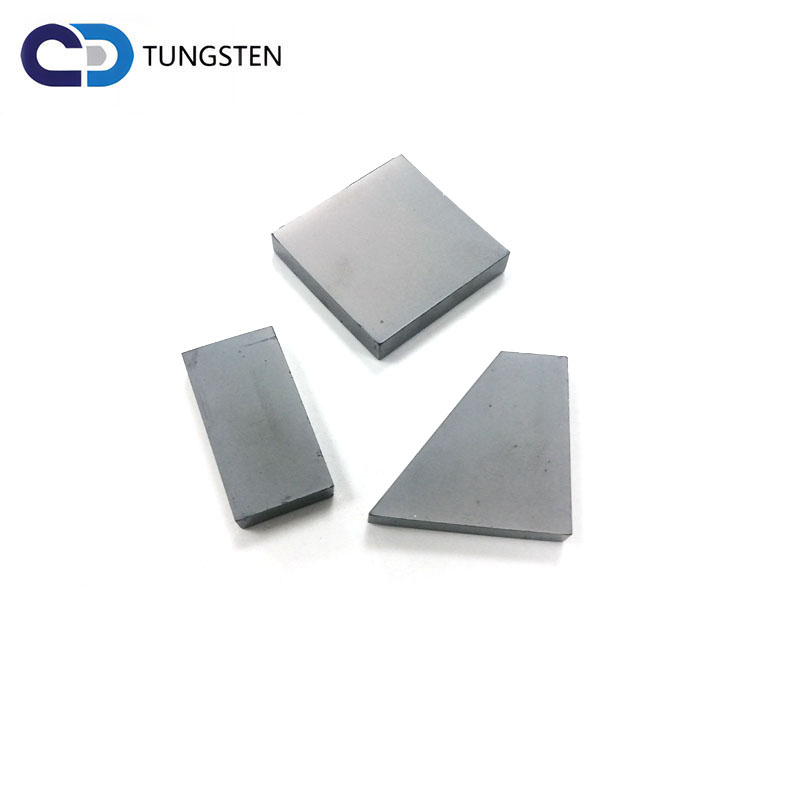

High Quality Square and Hexagonal Silicon Carbide Ceramic SIC Tiles Ceramic Plate For Armor Plate

Product description:

Products | SiSIC plate |

Characteristic | SiSiC plate is a new advanced silicon carbide material,which developed on the basis of primary high performance RSIC and NSIC and an economic and valueadded product with feartures of high degree of reliability,longer working life,and energy efficiency. |

Application | SiSiC plate are widely applied in sanitary ware,electric ceramics,and tableware industries.structural parts could service in coal,metallurgy,enwironment,construction tiles,electronic ceramics,chemical,and mechanics industries. |

Technical data

| item | unit | data |

| temperature of application | C | 1380 |

| density | g/cm3 | >=3.02 |

| open porosity | % | <0.1 |

| bending strength | Mpa | 250(20C) |

| Mpa | 280(1200C) |

| modulus of elasticity | Gpa | 330(20C) |

| Gpa | 300(1200C) |

| thermal conductivity | W/m.k | 45(1200C) |

| coefficient of thermal expansion | K-1*10-6 | 4.5 |

| rigidity |

| 13 |

| acid-proof alkaline |

| Excellent |

Product Features:

1. High temperature tolerance

2. Corrosion resistance

3. High bending strength

4. Oxidation resistance.High temperature Silicon carbide beam,

5.high temperature kiln furniture, SiSiC beam

The process of producing:

1) Silicon carbide refractory brick is made of sic raw material, mixed with SiO2 and C.

2) With all the material contact fully, the brick will be pressed under friction press, vibration molding, casting according to its shape.

3) After the billet making, it should be dried under room temperature for 2-3 days.

4)Then it will be sinstered in the high temperature furnace, pass through temperature rise period, temperature constant and temperature cooling period.

5) After sinstered, high quality bricks will be selected.

6) Seaworthy packing and timely delivery are supplied

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factory display

CONTACT US

info@zztungsten.com