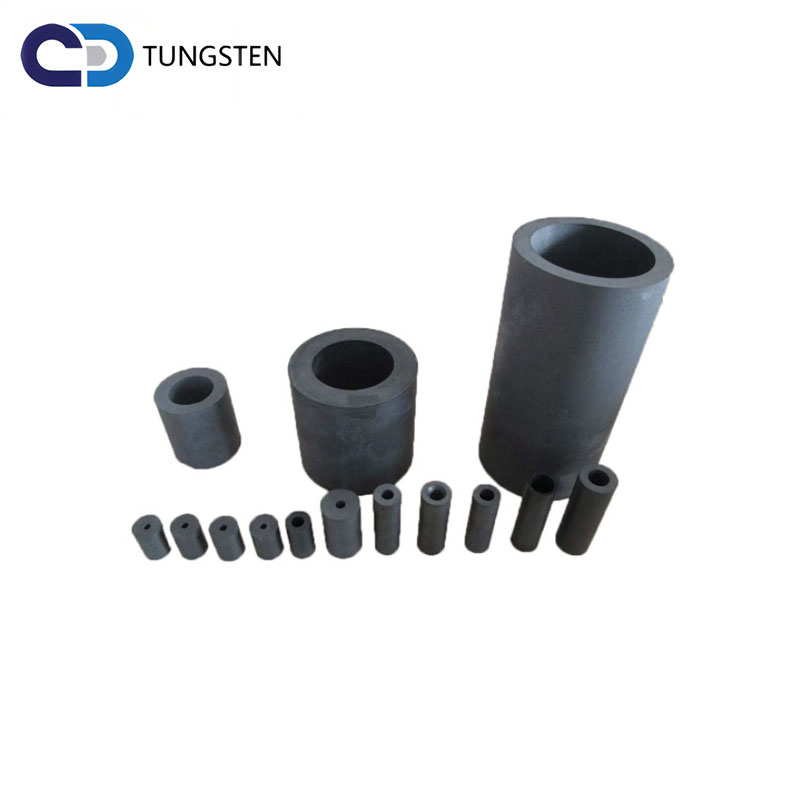

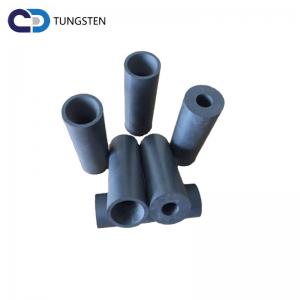

B4C Boron Carbide punching stamping die roll ring roller

Feature :

Superior wear resistance, impact resistance and corrosion resistance

Excellent flatness and temperature resistance up to 1380℃

Excellent oxidation resistance

Good dimensional control of complex shapes

Easy installation

Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

Application :

with high strength,high wear resistantce are widely used in papermaking, chemical, electronics, pharmaceutical and other ink jet,lithium battery materials, electronic pulp nano-ceramic sanding machines.

B4C Boron Carbide punching stamping die roll ring roller

| Name | Unit | B4C |

| Density | g/cm3 | >2.48 |

| Porosity | % | <0.5 |

| Vickers Hardness | HV1(GPa) | 26 |

| Young’s Modulus | GPa | 410 |

| Flexural Strength | MPa | 460 |

| Compressive Strength | MPa | >2800 |

| Fracture Toughness | MPa .m0.5 | 5 |

| Coefficient of thermal expansion 25℃-500℃ | 10 -6 /K | 4.5 |

| Coefficient of thermal expansion 25℃-500℃ | 10 -6 /K | 6.3 |

| 500℃-1000℃ |

|

|

| W/mK | 36 |

| Thermal conductivity at 25℃ |

| Ω cm | 1 |

| Specific electrical resistance at 25℃ |

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factory display

CONTACT US

info@zztungsten.com