Tungsten alloy ball is a spherical object made by alloying tungsten with other metals (such as nickel, iron or copper), and has the excellent properties of tungsten and its alloys. Tungsten alloy ball combines the high density and hardness of tungsten with the machinability of alloying elements, making it widely used in many fields. Its main properties include:

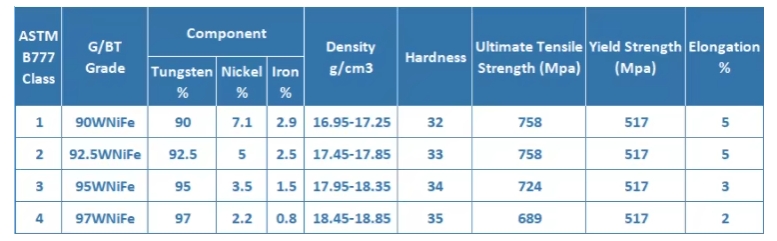

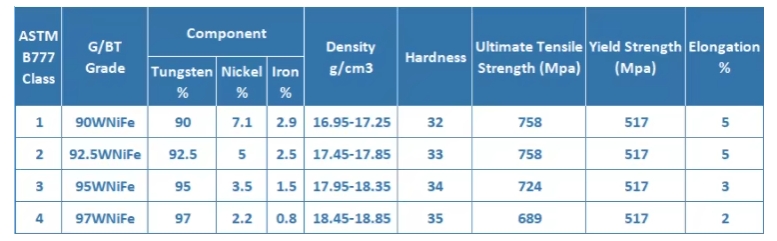

High density: The density of tungsten alloy balls is usually between 16-19 g/cm3, which makes them heavier than many other metals in the same volume, suitable for applications that require high mass weight.

High strength: Tungsten alloy balls have excellent mechanical strength and hardness, better toughness and impact resistance than pure tungsten, and are suitable for environments with high loads.

High melting point: The melting point of tungsten alloy ball is close to the melting point of tungsten (3422°C). Although alloying will slightly reduce the melting point, it can still work stably in high temperature environments.

Excellent wear resistance: Tungsten alloy balls have excellent wear resistance and are suitable for applications with frequent friction and impact.

Good processability: Compared with pure tungsten, tungsten alloy is easier to process into various shapes and sizes to meet the customized needs of different applications.

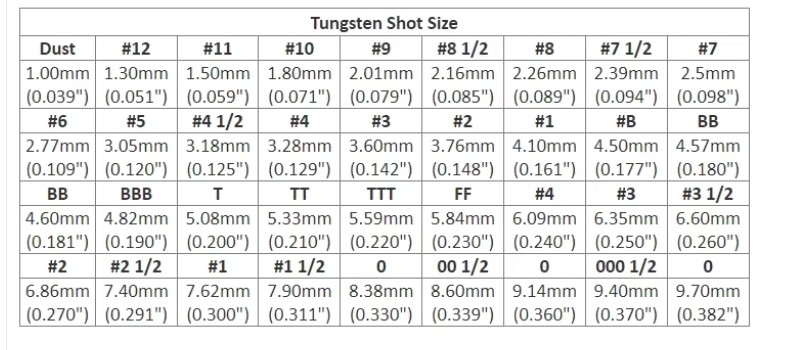

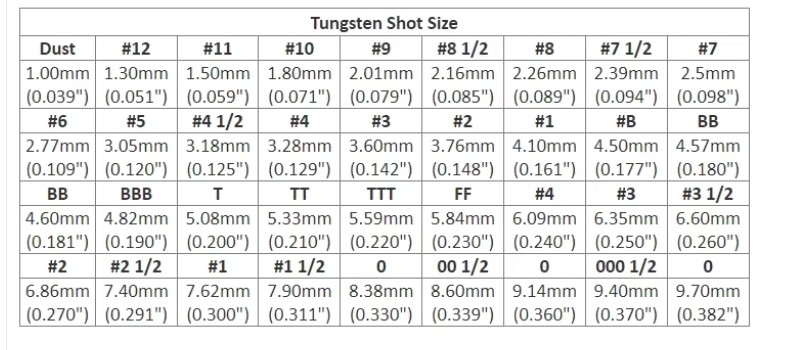

Product size

Tungsten alloy balls have a very wide range of sizes and can be customized according to customer needs. Common tungsten alloy ball diameter ranges include:

Small tungsten alloy balls: The diameter is usually between 1 mm and 10 mm, and are often used for balance and counterweights in precision instruments and micro-devices.

Medium tungsten alloy balls: The diameter ranges from 10 mm to 50 mm. Tungsten alloy balls of this size are widely used in mechanical engineering, sports equipment and aerospace.

Large tungsten alloy balls: The diameter exceeds 50 mm, which is suitable for industrial applications such as balance balls for large equipment and heavy weights.

Application fields

Tungsten alloy balls play an important role in many fields due to their unique physical and mechanical properties:

Aerospace: In the aerospace field, tungsten alloy balls are used for counterweights and stabilization devices to help adjust the center of gravity of aircraft and spacecraft and enhance their stability and maneuverability.

Military defense: In the military field, tungsten alloy balls are used to manufacture high-density armor-piercing projectiles, missiles and other precision weapon systems. Their excellent penetration ability and impact resistance make them an important part of protective materials.

Mechanical engineering: Tungsten alloy balls are often used for balance and shock absorption in industrial machinery, especially in high-speed rotation and high-load equipment to reduce vibration and wear.

Sports equipment: In high-end sports equipment, tungsten alloy balls are used to adjust the weight distribution and center of gravity of the equipment to optimize sports performance and comfort.

Scientific research experiments: In scientific research, tungsten alloy balls are used in high-temperature and high-pressure experimental environments. Their excellent stability and high-temperature resistance make them ideal experimental materials.

Zhuzhou Chuangde Cemented Carbide Co., Ltd. is committed to providing you with tailor-made solutions to meet your specific needs in aerospace, military defense, mechanical engineering, sports equipment and scientific research experiments. Choose our tungsten alloy balls, you will experience industry-leading technical support and excellent customer service. Contact us now to explore more product information and customized services about tungsten alloy balls, and jointly promote your project to new heights!