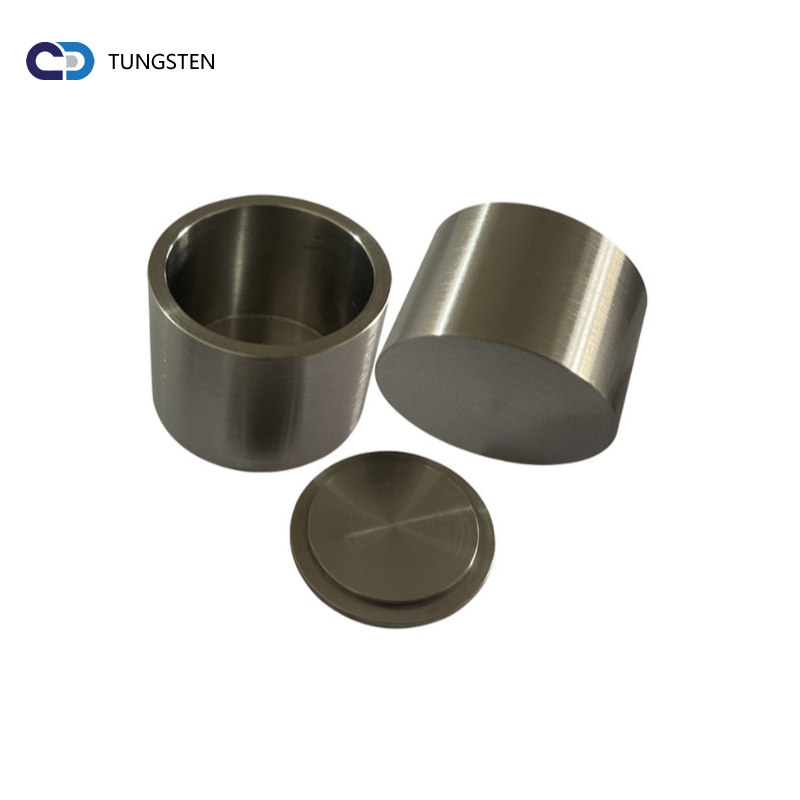

99.95% Purity Pure Tungsten Melting Pot tungsten crucible for sapphire growth furnace components

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Kí nìdí Yan Wa:

1. O le gba ohun elo pipe gẹgẹbi ibeere rẹ ni iye owo ti o kere julọ.

2. A tun nfun Awọn atunṣe, FOB, CFR, CIF, ati ẹnu-ọna si awọn owo ifijiṣẹ ẹnu-ọna. A daba pe ki o ṣe adehun fun gbigbe eyiti yoo jẹ ọrọ-aje pupọ.

3. Awọn ohun elo ti a pese jẹ iṣeduro patapata, lati ọtun lati ijẹrisi idanwo ohun elo aise si alaye iwọn ipari. (Awọn ijabọ yoo ṣafihan lori ibeere)

4. iṣeduro lati fun esi laarin awọn wakati 24 (nigbagbogbo ni wakati kanna)

5. O le gba awọn yiyan ọja iṣura, awọn ifijiṣẹ ọlọ pẹlu idinku akoko iṣelọpọ.

6. A ti wa ni kikun igbẹhin si awọn onibara wa. Ti ko ba ṣee ṣe lati pade awọn ibeere rẹ lẹhin idanwo gbogbo awọn aṣayan, a kii yoo tan ọ jẹ nipa ṣiṣe awọn ileri eke eyiti yoo ṣẹda awọn ibatan alabara to dara.

Ifihan ile-iṣẹ

PE WA

info@zztungsten.com