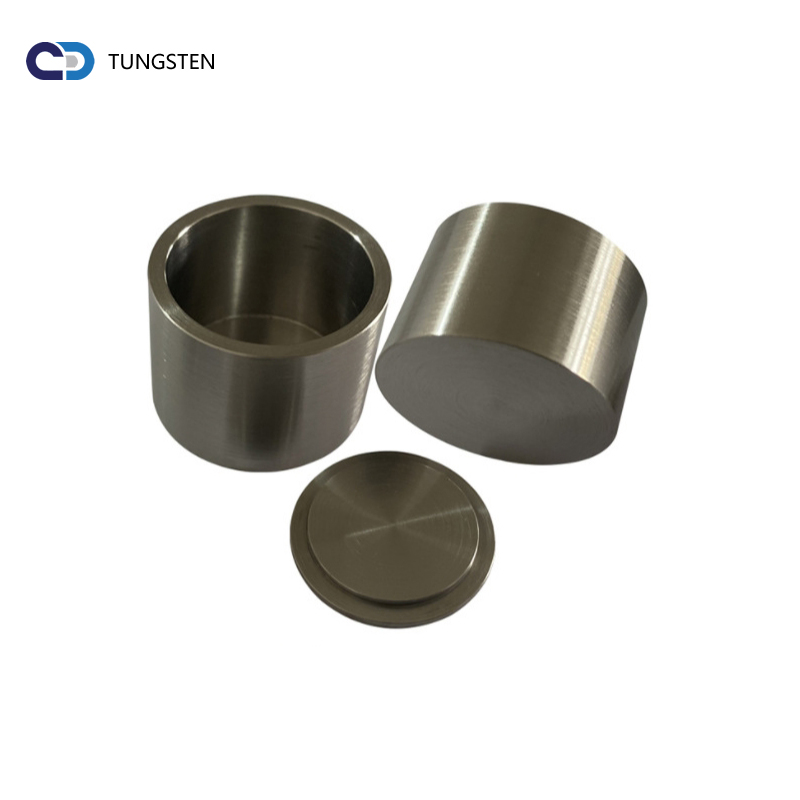

Wholesale High Temperature Sinter Tungsten Melting Crucible for Laboratory

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Näme üçin bizi saýlaň:

1. Iň az bahadan talaplaryňyza görä ajaýyp material alyp bilersiňiz.

2. Şeýle hem, Reworks, FOB, CFR, CIF we gapydan gapylara eltiş bahalaryny hödürleýäris. Shük daşamak üçin gaty tygşytly iş etmegi maslahat berýäris.

3. Biziň berýän materiallarymyz, çig mal synag şahadatnamasyndan iň soňky ölçeg beýanyna çenli doly barlanýar. (Hasabatlar talap boýunça görkeziler)

4. 24 sagadyň dowamynda jogap bermegi kepillendiriň (köplenç şol bir sagatda)

5. Önümçilik wagtyny azaltmak bilen aksiýa alternatiwalaryny, degirmen önümlerini alyp bilersiňiz.

6. Müşderilerimize doly wepaly. Optionshli wariantlary gözden geçireniňizden soň talaplaryňyza laýyk gelmeýän bolsa, gowy müşderi gatnaşyklaryny döredjek ýalan wadalar berip sizi ýalňyşmarys.

Zawodyň ekrany

BIZ bilen habarlaşyň

info@zztungsten.com