Tungsten koporo boat poleiti die bao e seng likarolo tse tloaelehileng

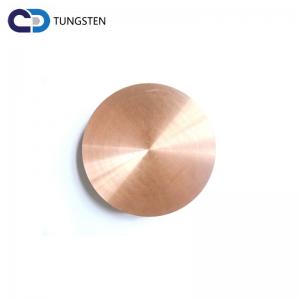

Tlhaloso ea Sehlahisoa

| Sehlahisoa | motsoako oa koporo oa tungsten |

| Lintho tse bonahalang | W+Copper+Ni |

| Kereiti | W+Copper+Ni |

| Boholo ba lijo-thollo | hantle, mahareng |

| Ho thatafala | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Bokaholimo | e se nang letho kapa fatshe |

| Kopo | koaele e tiisitsoeng bakeng sa transistors sealing welder, lisebelisoa tsa khokahanyo bakeng sa li-switches tse phahameng tsa motlakase le li-electrode bakeng sa ts'ebetso ea spark jj. |

Mefuta, metsoako ea lik'hemik'hale le thepa ea mantlha:

Mofuta | sebopeho sa lik'hemik'hale tsa koporo tungsten alloy (%) | resistivity(cm) | matla a thata (kg/mm2) | thatafalo | density(g/cm3) |

W | Cu |

CD1-3 | 60 | tekatekano | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Brand le NO. | Likarolo tsa lik'hemik'hale% | Lintho tsa 'mele |

Cu | Litšila kaofela ≤ | W | Botenya (g/cm³) ≥ | Ho thatafala HB ≥ | Ho hanyetsa (µΩ·cm) ≤ | Boikhantšo IACS%≥ | Matla a kobehang Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Karolo ea Sehlahisoa :

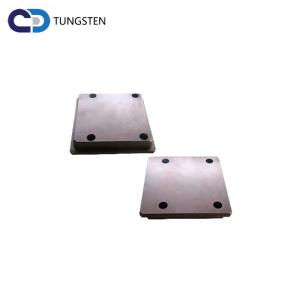

1.Ho hanyetsa mocheso ho molemo

2.Betere ablate-resistance

3.Boima bo phahameng

4.Matla a phahameng

5.Mocheso o motle haholo le conductivity ea motlakase

6.Ho bonolo ho etsoa ka mochine

Lisebelisoa tsohle tsa rona li hlahisoa ke mochine oa khatiso, sinter, lets'ebetso ea ho kenella. E mong le e mong oa tlhahisomohato, ho kenyeletsoa le phofo ea motheo, e laoloa haholo, e behoa leihlo, 'me e saennoe ke Quality Assurance. Kamora ho phethoa, lotho tsohle tse entsoeng li hlahlojoa bakeng sa conductivity, density, le ho thatafala pele ho thomello. Tlhahisoleseding ena e ngotsoe mme e bolokoe faeleng, hape e tsamaea le likarolo kapa thepa ha e kōptjoa.

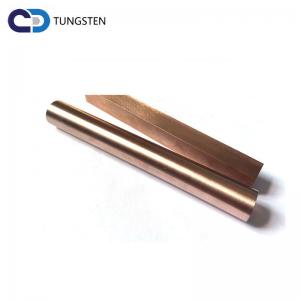

EDM le ECM

li-composite tsa tungsten li sebelisoa lefatšeng ka bophara bakeng sa li-electrode tsa EDM (Electrical Discharge Machining) le ECM (Electrochemical Machining). Lisebelisoa tsohle li etsoa ke mochine oa khatiso, sinter, le mokhoa oa ho kenella. Li-powders tsa moroetsana li sebelisoa, e leng se etsang hore ho be le thepa e lumellanang e fanang ka litheko tse phahameng esita le tse tukang. Tungsten ea koporo e sebelisoa lits'ebetsong tsa plunger/sinker moo ho hlokahalang tlhaloso e rarahaneng, haholo-holo tungsten carbide.

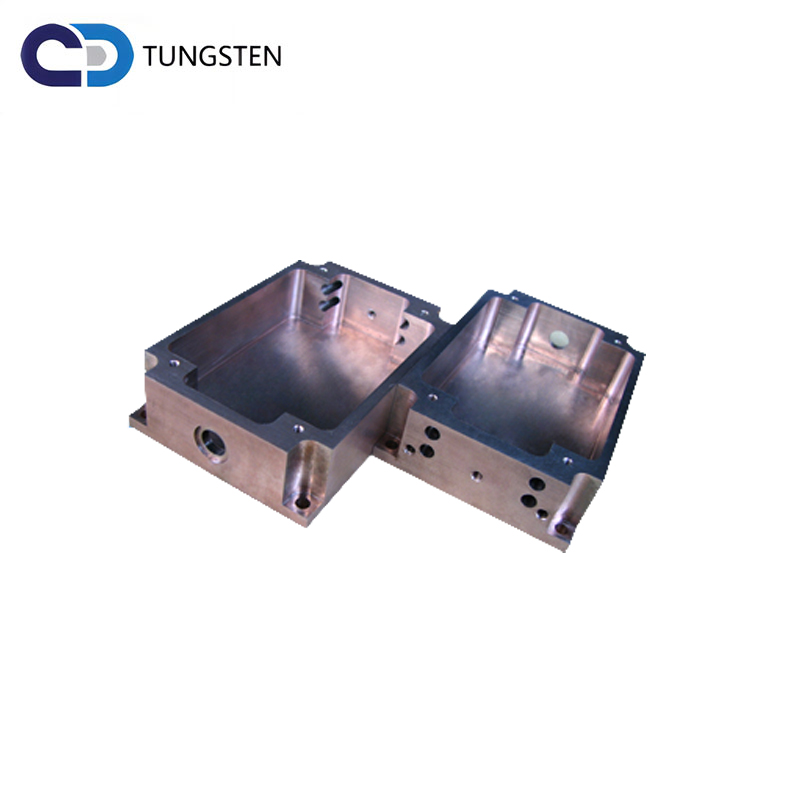

Litekanyo

Libolo: φ 1.5mm -φ 100mm

Shafts: (φ1mm ka holimo) × (Bolelele max.600mm)

Maqephe: (Botenya 0.15mm ka holimo) × (Bophahamo bo boholo.200mm) × (Bolelele max.500mm)

Bophahamo ba lisekoere, tse chitja le tse khutlonnetsepa: bophara ba 550mm ka holimo

Ho latela ba batlang

Ke Hobane'ng ha U Re Khetha:

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. tiisetso ea ho fana ka karabo nakong ea lihora tse 24(hangata ka hora e tšoanang)

5. U ka fumana mefuta e meng ea li-stock, ho tsamaisoa ha leloala ka ho fokotsa nako ea tlhahiso.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

Pontšo ea feme

ITEANYE LE RONA

info@zztungsten.com