Ka tsoelo-pele e tsoelang pele ea theknoloji ea indasteri, lisebelisoa tse ncha le mekhoa e mecha li tsoela pele ho hlaha.Bucking Bars,joalo ka sesebelisoa sa bohlokoa sa khokahano, le tsona li lula li ntlafatsoa le ho nchafatsoa ho fihlela litlhoko tsa lisebelisoa tse ncha le lits'ebetso tse ncha. Ka mohlala, e le ho finyella litlhoko tsa boima bo bobebe le matla a phahameng sebakeng sa lifofane, li-Bucking Bars tse entsoeng ka lisebelisoa tse phahameng tse kang li-alloys tsa tungsten li entsoe. Tšebeliso ea lisebelisoa tsena tse ncha e khothalelitse tsoelo-pele ea theknoloji ea sepakapaka.

Tungsten Bucking Bar ke eng?

Tungsten Bucking bar ke sesebelisoa sa mosebetsi se amoheloang ka mor'a sebaka sa mosebetsi ho fana ka setho se ts'ehetsang ho sebelisa li-fasteners le ho kenyelletsa hlooho ea lithulusi e kenelletseng le likarolo tse nang le sekhechana se tlase se monyang matla se fang moo betwe.st ho nka meroalo e tshosang ka ho hatella le ho kuta.

Li-Bucking Bars li na le melemo e latelang ha li bapisoa le lisebelisoa tse ling tsa khokahano

Melemo:

1. Matla a khokahanyo e phahameng le ho tšepahala:

Nakong ea ts'ebetso ea riveting, Li-Bucking Bars li fana ka tšehetso e tsitsitseng le e matla ka morao ea rivet, e ka senyang rivet ka nepo le ho theha khokahanyo e matla. Mokhoa ona oa ho hokahanya o ka mamella meroalo e meholo e kang tsitsipano, khatello le matla a ho kuta. Ha ho bapisoa le likhokahano tse ling tsa sekhomaretsi kapa likhokahano tse bonolo tsa ferrule, matla a eona a khokahano le ts'epahalo li betere, 'me e loketse meaho e nang le litlhoko tse phahameng tsa matla a khokahanyo, joalo ka li-fuselage tsa sefofane, marokho, liforeimi tsa moaho, jj.

Tlas'a ts'ebeliso ea nako e telele kapa maemo a thata a ts'ebetso a kang ho sisinyeha le liphetoho tsa khatello ea kelello, mohaho o kopantsoeng ke Bucking Bars o ntse o ka boloka botsitso bo botle 'me ha o khone ho lokoloha kapa ho hlōleha ha khokahanyo.

Tšebeliso e pharaletseng:

2. Ho ikamahanya le maemo ho matla: Li-Bucking Bars tsa lisebelisoa tse fapaneng li ka khethoa ho latela litlhoko tse fapaneng tsa mosebetsi ho ikamahanya le riveting ea lisebelisoa tse fapaneng.

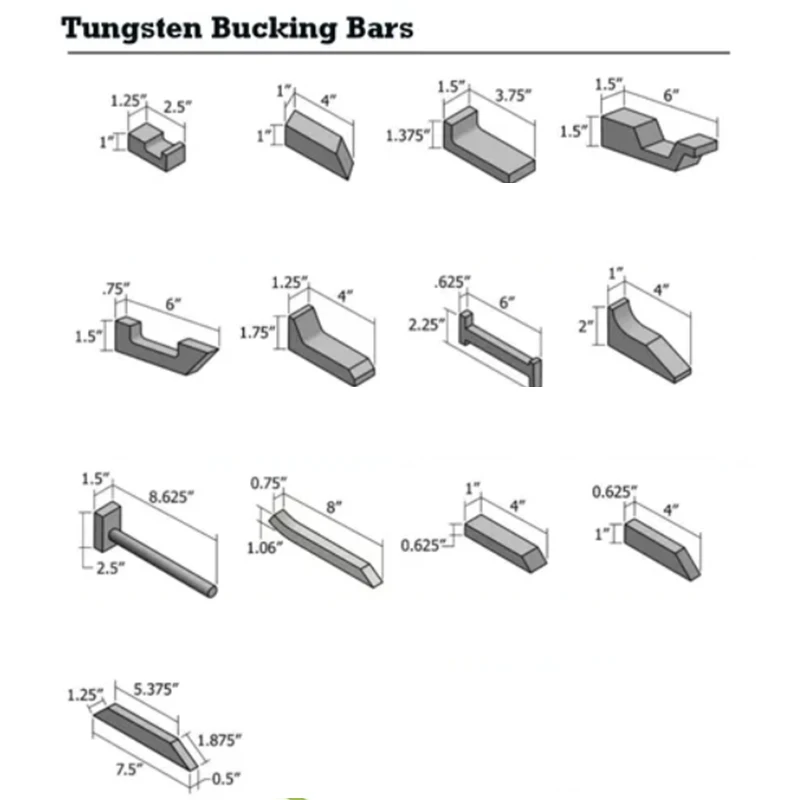

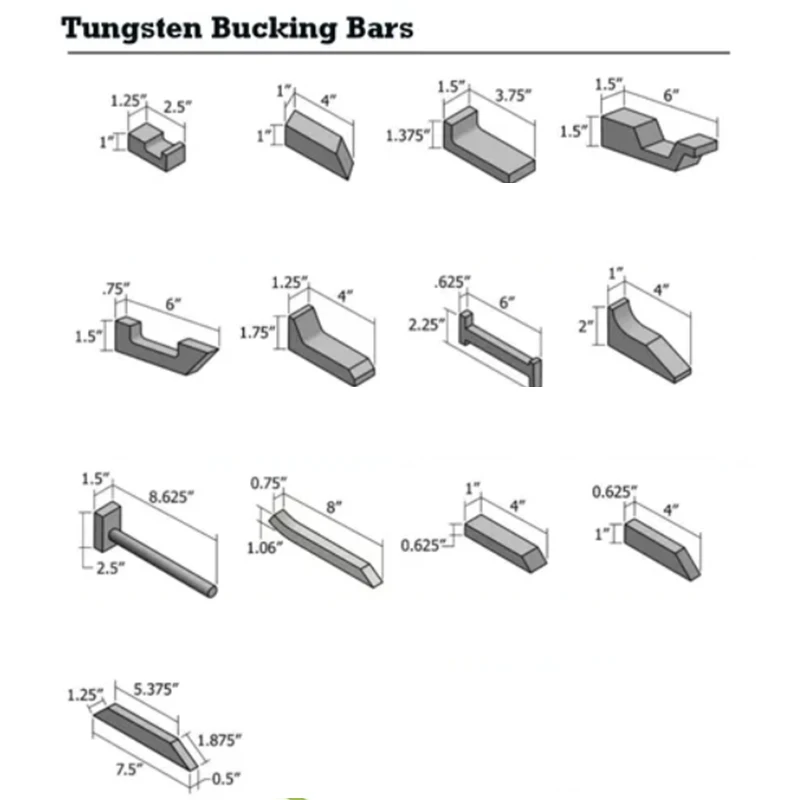

3. E loketse meaho e rarahaneng: Sebopeho sa eona le boholo ba eona li ka etsoa le ho etsoa ka mokhoa o ikhethileng ho ea ka maemo a ikhethileng a mosebetsi, 'me e ka sebetsoa ka meaho e nang le libopeho tse rarahaneng le libaka tse moqotetsane, joalo ka liphaephe tse kobehileng, likheo tse moqotetsane, meaho e nang le sebopeho se ikhethileng, jj. ., eo ho leng thata ho lisebelisoa tse ling tse ngata tsa khokahano ho e etsa.

4. Ho bonolo ho sebetsa: Li-Bucking Bars li sebelisoa hammoho le lisebelisoa tse kang lithunya tsa rivet, 'me ts'ebetso ea ts'ebetso e batla e le bonolo.

Linyeoe tse ikhethileng tsa ts'ebeliso ea li-Bucking Bars libakeng tse fapaneng

1. Sepakapaka

Sefofane sa fuselage kopano: Nakong ea ts'ebetso ea ho etsa lifofane, ho hlokahala palo e kholo ea riveting pakeng tsa letlalo la fuselage le foreimi. Mohlala, kopanong ea fuselage ea lifofane tsa baeti tse kang Boeing 737 le Airbus A320, Li-Bucking Bars li sebelisoa ho etsa bonnete ba hore li-rivets li hokahanya letlalo le foreimi ka thata.

Khokahano ea karolo ea enjene: Enjene ea sefofane ke karolo ea mantlha ea sefofane, 'me likarolo tse ling tsa mocheso o phahameng le likarolo tse ka hare ho eona le tsona li hloka ho hokahanngoa ka riveting. Ka mohlala, kamano pakeng tsa lehare la enjene le hub ea lebili e ka phethoa ka nepo ka ho sebelisa Bucking Bars. Ho kenngoa ha li-rivets ho lumella lehare hore le be le botsitso holim'a hub ea mabili.

2. Sebaka sa ho etsa likoloi

Kopano ea foreimi ea 'mele: Ha ho etsoa liforeimi tsa 'mele oa koloi, lishiti tsa tšepe tsa libopeho tse fapaneng le botenya li hloka ho kopanngoa. Ka mohlala, ts'ebetsong ea kopano ea foreimi ea 'mele oa koloi, Li-Bucking Bars li sebelisetsoa ho hokahanya likarolo tse kang maballo a mahlakoreng, maballo a sefapano le liforeimi tsa marulelo. Khokahano e matla e ka fana ka matla a lekaneng ho mamella torsion le matla a matla nakong ea ho khanna koloi. Ka nako e ts'oanang, ha ho bapisoa le welding, riveting e ka fokotsa deformation ea 'mele le ho ntlafatsa ho nepahala ha kopano ea' mele.

Ho kenya setulo sa koloi: Riveting e boetse e sebelisoa hangata ho lokisa litulo tsa koloi. Li-Bucking Bars li sebelisetsoa ho kenya li-rivets tsa ho lokisa litulo e le hore litulo li khone ho mamella matla a inertial a hlahisoang ke ho qhoqhoa ka tšohanyetso, ho chenchana ka bohale, joalo-joalo, ho etsa bonnete ba hore litulo li ke ke tsa theoha.

3. Tšimo ea ho haha likepe

Ho kopanya khetla ea Hull: Ha ho etsoa likepe, khetla ea hull e kopantsoe ke likarolo tse ngata tsa lipoleiti tsa tšepe. Ka mohlala, ts'ebetsong ea ho etsa likepe tsa thepa ea lithane tse 10,000, Bucking Bars e sebelisoa ho kopanya likotoana tsa lipoleiti tsa tšepe ka ho riveting. Kaha likepe li angoa ke lintho tse fapaneng tse kang ho bola ha metsi a leoatle, tšusumetso ea maqhubu le khatello ea thepa nakong ea ho tsamaea, mokhoa ona oa ho riveting o ka etsa bonnete ba ho tiisa le matla a sebopeho sa sekepe le ho thibela metsi a leoatle ho kena ka har'a sekepe.

Kaho ea mohaho oa ka hare oa sekepe: Li-bulkheads tse ling tsa karohano le meaho ea tšehetso ea mokatong oa sekepe le tsona li hahiloe ka riveting. Li-Bucking Bars li ka thusa ho phethela ho kenngoa ha li-rivets kahong ea mehaho ena e rarahaneng ea ka hare, ho etsa hore mohaho oa ka hare oa sekepe o be o tiileng le o ka tšeptjoang, o fana ka tšireletso bakeng sa ho tsamaea ka mokhoa o sireletsehileng oa sekepe le ho boloka thepa.

4. Sebaka sa kaho

Khokahano ea mohaho oa mohaho oa tšepe: Mehahong ea mohaho oa tšepe, joalo ka kaho ea foreimi ea li-gymnasium tse kholo, liholo tsa lipontšo le mehaho e meng, Li-Bucking Bars li sebelisetsoa ho hokahanya likarolo tsa mohaho tse kang maballo a tšepe le litšiea tsa tšepe. Mohlala, nakong ea kaho ea foreimi ea tšepe ea Lebala la Lipapali la Sechaba "Sehlaha sa Nonyana", Li-Bucking Bars li ne li sebelisetsoa likhokahano tse ling tsa rivet. Mokhoa ona oa ho hokahanya o ka netefatsa botsitso le polokeho ea mehaho ea mohaho oa tšepe tlas'a maemo a boima ba bona, meroalo ea moea, matla a tšisinyeho ea lefatše, joalo-joalo.

Ho kenya lerako la lerako: Ho kenngoa ha marako a likharetene tsa mohaho ka linako tse ling ho boetse ho etsoa ka riveting. Li-Bucking Bars li ka thusa ho hokahanya foreimi ea tšepe kapa poleiti ea lerako la lesira le mohaho o moholo oa mohaho, ho etsa bonnete ba hore lerako la lesira le ka lula le tsitsitse tlas'a maemo a sa tšoaneng a leholimo (joaloka meea e matla, lipula tse matla, joalo-joalo), le e na le tiiso e ntle ho thibela pula le moea o kenang.

5. Tšimo ea ho etsa thepa ea elektronike

Kopano ea likhetla tsa chassis: Ha ho etsoa chassis ea lisebelisoa tsa elektroniki, joalo ka chassis ea seva, chassis ea komporo, joalo-joalo, Li-Bucking Bars li sebelisoa ho hokahanya likarolo tsa khetla ea chassis. Li-chassis tsena li hloka ho netefatsa ts'ebetso e itseng ea ts'ireletso ea motlakase le matla a mochini. Riveting e ka etsa hore khetla e hokahane ka thata ho fihlela litlhoko tsa tšireletso ea motlakase, 'me ka nako e ts'oanang e khone ho mamella likhohlano tse itseng le li-extrusions ho sireletsa likarolo tsa elektroniki tsa kahare.

Ho lokisa radiator: Radiator ea lisebelisoa tsa elektroniki hangata e hloka ho ts'oaroa ka thata holim'a chip kapa likarolo tse ling tsa ho futhumatsa. Li-server tse ling tsa maemo a holimo kapa lik'homphieutha tsa taolo ea indasteri, Li-Bucking Bars li sebelisetsoa ho kenya li-rivet ho lokisa radiator ho netefatsa hore ho na le kamano e ntle pakeng tsa radiator le mocheso oa mocheso, ka tsela eo ka katleho e felisa mocheso le ho thibela thepa hore e senyehe ka lebaka la ho chesa haholo.

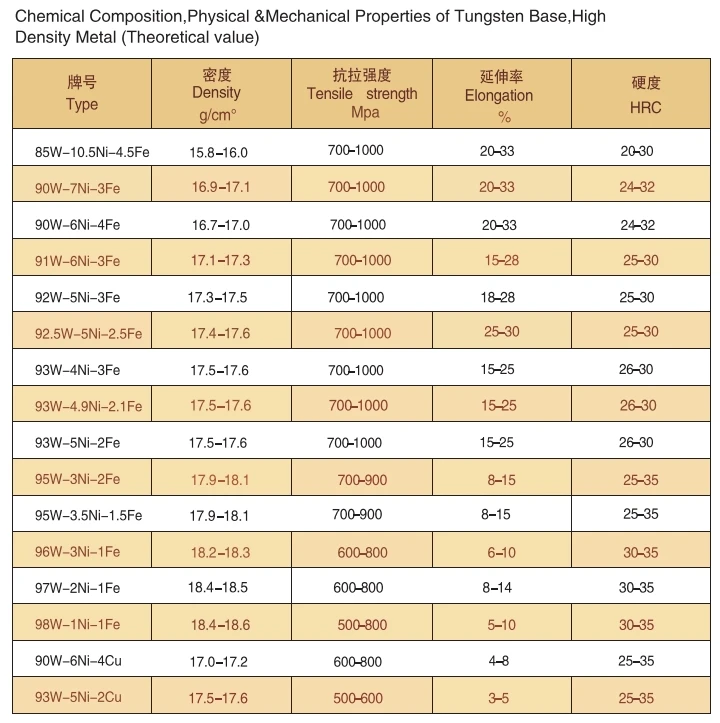

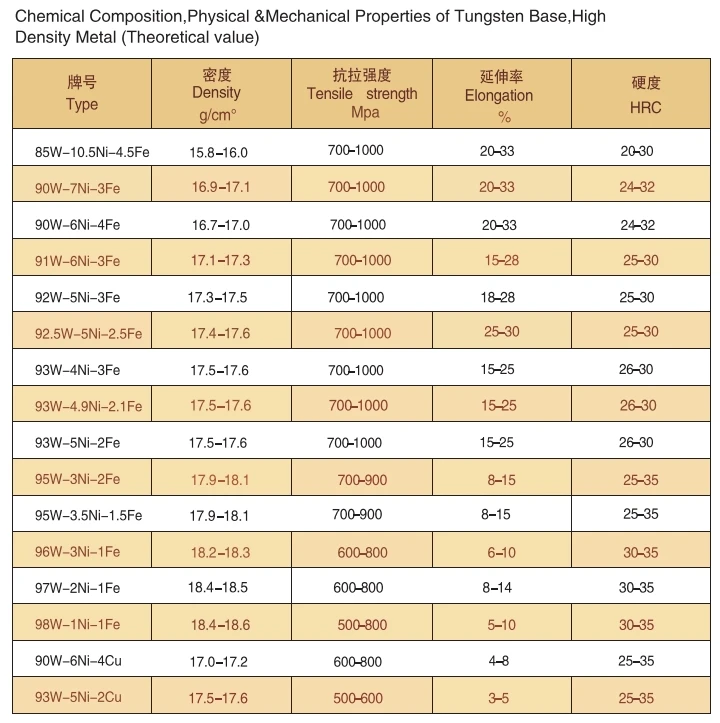

Ka kakaretso, WNiFe tungsten alloy bucking bar e bapala karolo ea eona e ikhethang masimong a mangata. Ha u khetha bar ea bucking, u tlameha ho khetha boemo bo nepahetseng ba thepa ho latela litlhoko tse ikhethileng tsa ts'ebeliso le tikoloho ea ts'ebetso ho netefatsa ts'ebetso ea eona le bophelo ba ts'ebeletso.

Lipontšo tsa rona tsa Profuct