Saxanka doonta naxaasta Tungsten dhiman qaybo aan caadiga ahayn

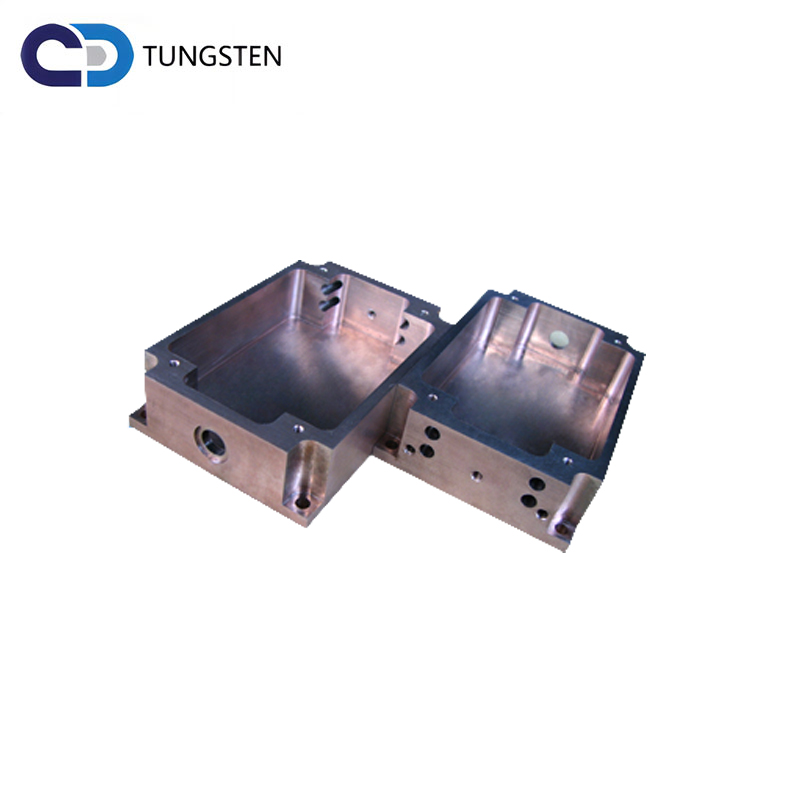

Sharaxaada badeecada

| Alaabta | tungsten copper alloy |

| Qalab | W+Copper+Ni |

| Darajo | W+Copper+Ni |

| Cabirka Hadhuudhka | fiican, dhexdhexaad ah |

| Adag | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Dusha sare | bannaan ama dhul |

| Codsiga | dabool daboolan oo loogu talagalay transistor-yada alxanka shaabadeynta, alaabada xiriiriyaha ee furayaasha korantada sare iyo korantada farsamaynta dhimbilaha iwm. |

Noocyada, ka kooban kiimikaad iyo sifooyinka ugu muhiimsan:

Nooca | Halabuurka kiimikaad ee naxaasta tungsten alloy (%) | iska caabin (cm) | xoogga xajinta (kg/mm2) | qallafsanaan | density(g/cm3) |

W | Cu |

CD1-3 | 60 | dheelitirnaan | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Summada iyo MAYA. | Qaybaha kiimikada% | Tilmaamaha jirka |

Cu | Wadarta wasakhda ≤ | W | Cufnaanta (g/cm³) ≥ | Adag HB ≥ | iska caabin (µΩ·cm) ≤ | Hab-dhaqanka IACS%≥ | Xoog laabashada Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

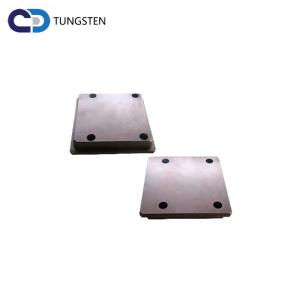

Sifada badeecada:

1.Iska caabbinta kulaylka wanaagsan

2.Iska caabin ka fiican

3.Cufnaanta sare

4.Xoogga sare

5.Heerarka kulaylka iyo korantada ee heer sare ah

6.Fudud in lagu farsameeyo

Dhammaan alaabtayada waxaa soo saaray saxafada, sinter, iyosoo dhex gasha. Wax soo saar kastatillaabada, oo ay ku jirto budada aasaasiga ah, si dhow ayaa loo kantaroolaa, loola socdaa, oo ay saxeexday Xaqiijinta Tayada. Dhammaystirka ka dib, dhammaan alaabooyinka la soo saaray waxaa laga hubiyaa dhaqdhaqaaqa, cufnaanta, iyo adkaanta ka hor inta aan la dhoofin. Macluumaadkan waa la duubay oo lagu hayaa faylka, sidoo kale waxay la socotaa qaybaha ama alaabta marka la codsado.

EDM iyo ECM

Isku-dhafka tungsten waxaa adduunka oo dhan loo isticmaalaa EDM (Machining Korontada) iyo ECM (Machining Electrochemical). Dhammaan walxaha waxaa soo saaray saxafada, sinter, iyo habka dhex galka. Budada bikrada ah ayaa la isticmaalaa, taasoo keentay in wax isku mid ah oo joogto ah oo siinaya heerar sare iyo xitaa gubasho. Tungsten Copper waxaa loo isticmaalaa codsiyada plunger/musqusha halkaasoo qeexitaan adag looga baahan yahay, gaar ahaan carbide tungsten.

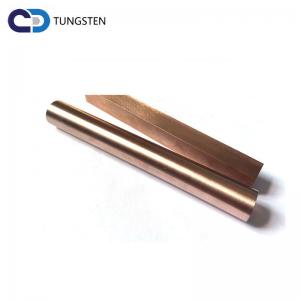

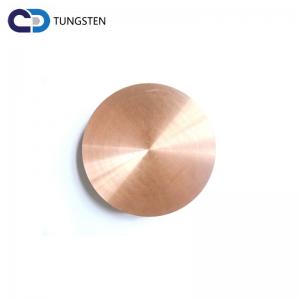

Cabirka

Kubadaha: φ 1.5mm -φ 100mm

Shafts: (φ1mm korka) × (dhererka max.600mm)

Xaashiyaha: (Qodhka 0.15mm ee ka sarreeya) × (Balacsanaanta max.200mm) × (Max.500mm)

Cabbirrada labajibbaaran, wareegsan iyo leydi: dhexroor 550mm korka

Sida loo dalbado

Maxaad noo doorataa:

1. Waxaad heli kartaa alaabta ugu fiican ee waafaqsan shuruudahaaga ugu yaraan qiimaha suurtogalka ah.

2. Waxaan sidoo kale bixinaa Dib-u-hawlgalayaasha, FOB, CFR, CIF, iyo albaabka ilaa albaabka qiimaha gaarsiinta. Waxaan kugula talineynaa inaad wax ka qabato dhoofinta kaas oo noqon doona mid aad dhaqaale.

3. Agabka aanu bixinayno gabi ahaanba waa la xaqiijin karaa, laga bilaabo shahaadada tijaabada alaabta ceyriinka ilaa qoraalka cabbirka kama dambaysta ah.

4. dammaanad qaadka inaad ku bixiso jawaab 24saac gudahood (badanaa isla saacada)

5. Waxaad heli kartaa beddelka kaydka, keenista wax-shiidka oo yaraynaysa wakhtiga wax-soo-saarka.

6. Waxaan si buuxda ugu heellan nahay macaamiishayada. Haddii ay suurtagal noqon waydo inaad buuxiso shuruudahaaga ka dib markaad eegto dhammaan fursadaha, kuma marin habaabin doonno ballanqaadyo been ah oo abuuraya xiriir wanaagsan oo macaamiisha ah.

Bandhig warshadeed

NALA SOO XIRIIR

info@zztungsten.com