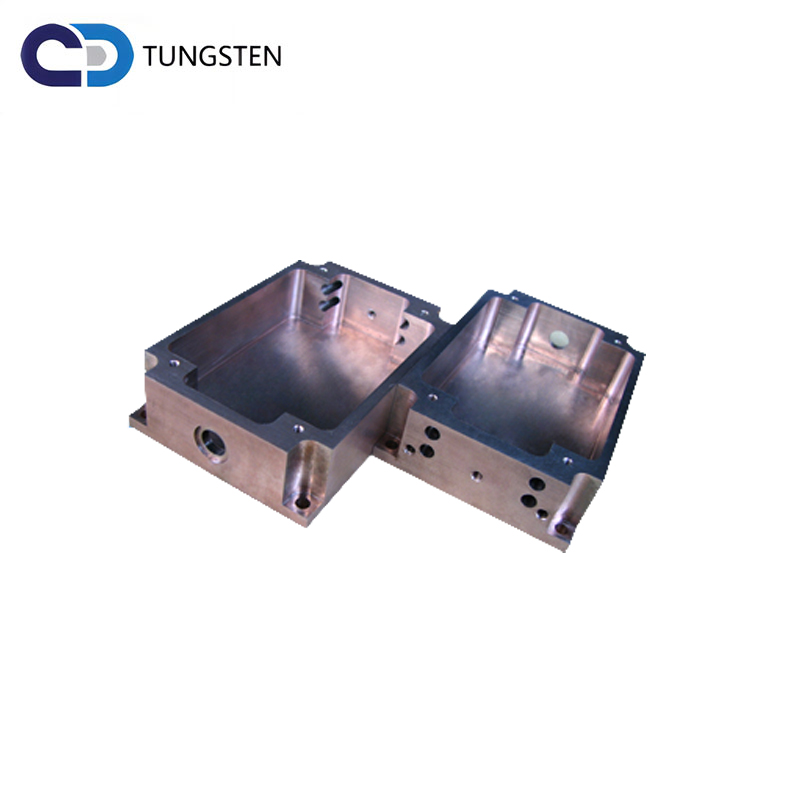

Tungsten mhangura yebhoti ndiro inofa isiri yakajairika zvikamu

Chigadzirwa tsananguro

| Product | tungsten mhangura alloy |

| Material | W+Copper+Ni |

| Giredhi | W+Copper+Ni |

| Saizi yezviyo | zvakanaka, pakati |

| Kuoma | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Surface | isina chinhu kana pasi |

| Application | yakavharwa chivharo che transistors sealing welder, contactor zvinhu zvehighvoltage switch uye maelectrodes e spark processing etc. |

Mhando, maumbirwo emakemikari uye huru zvivakwa:

Type | kemikari yemhangura tungsten alloy (%) | kuramba (cm) | kusimba simba (kg/mm2) | kuoma | density(g/cm3) |

W | Cu |

CD1-3 | 60 | balance | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Brand uye NO. | Chemical components% | Zvinhu zvemuviri |

Cu | Zvose zvisina kuchena ≤ | W | Density (g/cm³) ≥ | Kuoma HB ≥ | Resistivity (µΩ·cm) ≤ | Conductivity IACS%≥ | Kupeta simba Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Product feature:

1.Zviri nani kupisa kusagadzikana

2.Zvirinani ablate-resistance

3.High densisty

4.High intensity

5.Yakanakisa thermal uye elctrical conductivity

6.Zviri nyore kugadzirwa

Zvese zvezvishandiso zvedu zvinogadzirwa nemuchina, sinter, uyeinfiltrate process. Imwe neimwe yekugadziranhanho, kusanganisira hupfu hwekutanga, inodzorwa zvakanyanya, inotariswa, uye yakasainwa neKusimbisa Hunhu. Mushure mekupedzwa, mijenya yese inogadzirwa inotariswa kune conductivity, density, uye kuoma isati yatumirwa. Ruzivo urwu runorekodhwa uye kuchengetwa pafaira, uye zvakare runoperekedza zvikamu kana zvinhu kana zvakumbirwa.

EDM uye ECM

tungsten composites inoshandiswa pasi rose kune EDM (Electrical Discharge Machining) uye ECM (Electrochemical Machining) electrodes. Zvese zvinhu zvinogadzirwa nemuchina, sinter, uye infiltrate process. Mhandara hupfu hunoshandiswa, zvichikonzera kuenderana kune homogeneous zvinhu zvinopa yakakwirira uye kunyange kupisa mitengo. Copper tungsten inoshandiswa muplunger/sinker application panodiwa tsananguro yakaoma, kunyanya mu tungsten carbide.

Dimensions

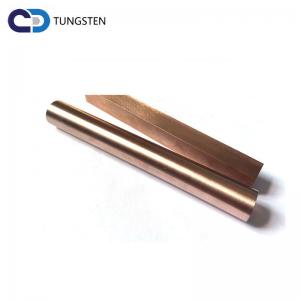

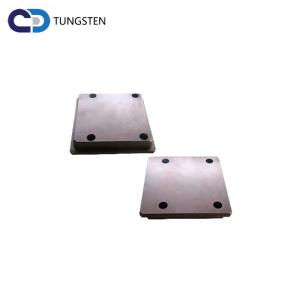

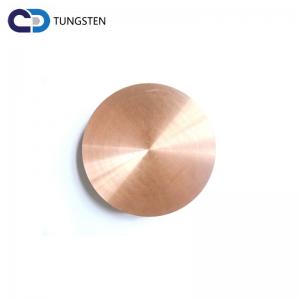

Mabhora: φ 1.5mm -φ 100mm

Mashefu: (φ1mm kumusoro) × (Kureba max.600mm)

Sheets: (Kukobvu 0.15mm kumusoro) × (Wideness max.200mm)× (Kureba max.500mm)

Sikweya, denderedzwa uye rectangle saizi: dhayamita 550mm kumusoro

Maererano nezvinodiwa

Sei Tisarudze:

1. Unogona kuwana zvinhu zvakakwana maererano nezvaunoda pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pagwaro rebvunzo retifiketi kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

4. vimbiso yekupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, zvigayo zvekutakura nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

Kuratidzwa kwefekitari

TAURA NESU

info@zztungsten.com