Tungsten apamemea ipu ipu mate vaega e le masani

Fa'amatalaga o oloa

| Oloa | tungsten apamemea apamemea |

| Meafaitino | W+Kopa+Ni |

| Vasega | W+Kopa+Ni |

| Tele o Saito | lelei, feololo |

| Malosi | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Laufanua | avanoa po o eleele |

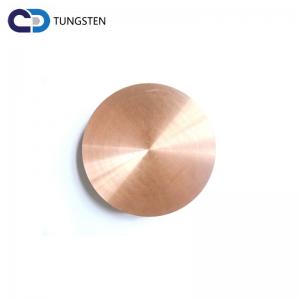

| Fa'atatauga | fa'amaufa'ailoga pulou mo transistors fa'amau fa'ailoga uelo, mea fa'afeso'ota'i mo su'ega maualuga ma eletise mo le fa'aogaina o aloiafi ma isi. |

Ituaiga, tuufaatasiga kemikolo ma meatotino autu:

Ituaiga | vailaʻau vailaʻau o kopa tungsten alloy(%) | resistivity(cm) | malosi mālosi(kg/mm2) | maaa | density(g/cm3) |

W | Cu |

CD1-3 | 60 | paleni | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Fa'ailoga ma LEAI. | Vaega vaila'au% | Meatotino faaletino |

Cu | Aofa'i le mama ≤ | W | Malosi (g/cm³) ≥ | Malosi HB ≥ | Tete'e (µΩ·cm) ≤ | Conductivity IACS%≥ | Malosi punou Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Fa'ailoga oloa:

1.Sili atu le vevela

2.Sili atu ablate-tetee

3.maualuga le mafiafia

4.Malosi maualuga

5.Lelei tele le vevela ma le elctrical conductivity

6.Faigofie ona fa'a masini

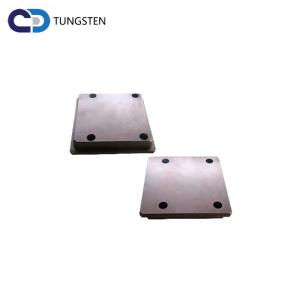

O a tatou mea uma e gaosia e le lomitusi, sinter, mafa'aulufale fa'agasologa. O gaosiga taitasiLaasaga, e aofia ai le pauta faavae, e vaʻaia lelei, mataʻituina, ma sainia e le Quality Assurance. A mae'a, e siaki uma le tele o fale gaosi mo le fa'aosoina, mamafa, ma le ma'a'a a'o le'i fa'atau. O lenei faʻamatalaga e faʻamaumau ma teuina i faila, ma faʻatasi ai ma vaega poʻo meafaitino pe a talosagaina.

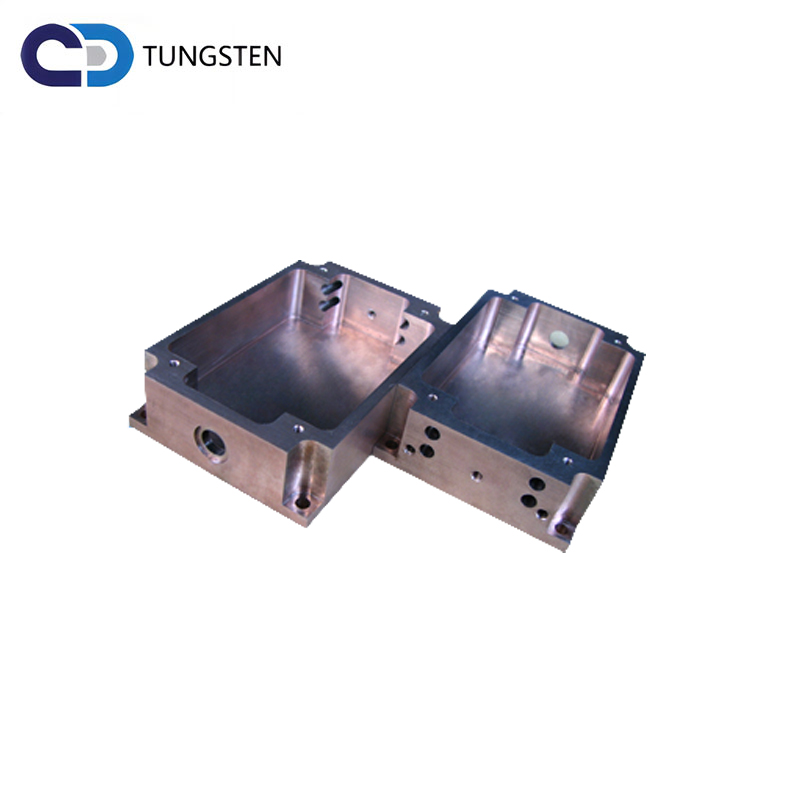

EDM ma ECM

tungsten composites o loʻo faʻaaogaina i le lalolagi atoa mo EDM (Electrical Discharge Machining) ma ECM (Electrochemical Machining) electrodes. O mea uma e gaosia e le lomitusi, sinter, ma le infiltrate process. O pa'u taupou o lo'o fa'aaogaina, e maua ai se mea tutusa tutusa e maua ai le maualuga ma le mu fua. O le tungsten apamemea e faʻaaogaina i le plunger / sinker applications lea e manaʻomia ai faʻamatalaga lavelave, aemaise lava ile tungsten carbide.

Fua

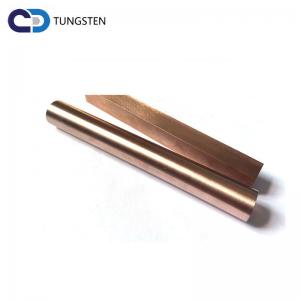

Polo: φ 1.5mm -φ 100mm

La'au: (φ1mm i luga) ×(Uumi max.600mm)

Pepa: (Mafiafi 0.15mm luga)×(Ateletele max.200mm)×(Uumi max.500mm)

Fa'atafafa, lapotopoto ma fa'afa'afa'afa lapoa: lautele 550mm luga

E tusa ai ma le manaoga

Aisea e Filifili ai Matou:

1. E mafai ona e mauaina le mea sili ona lelei e tusa ai ma lou manaʻoga i le tau maualalo.

2. Matou te ofoina atu foʻi Reworks, FOB, CFR, CIF, ma tau tuʻuina atu i le faitotoa. Matou te fautuaina oe e fai fefaʻatauaiga mo felauaiga o le a fai si taugofie.

3. O mea matou te tuʻuina atu e mafai ona faʻamaonia atoatoa, saʻo mai le tusi faʻataʻitaʻiga suʻega mataʻutia i le faʻamatalaga pito mulimuli.

4. faʻamautinoa e tuʻuina atu se tali i totonu ole 24 itula (masani ile itula lava e tasi)

5. E mafai ona e maua isi fa'atauga, fa'atauga fa'atau ma fa'aitiitia le taimi o gaosiga.

6. Matou te faʻamaoni atoatoa ia matou tagata faʻatau. Afai o le a le mafai ona ausia ou manaʻoga pe a uma ona suʻesuʻeina filifiliga uma, matou te le faʻasesēina oe e ala i le faia o folafolaga pepelo e faʻatupuina sootaga lelei tagata faʻatau.

Fa'aaliga falegaosimea

FAAFESOOTAI MATOU

info@zztungsten.com