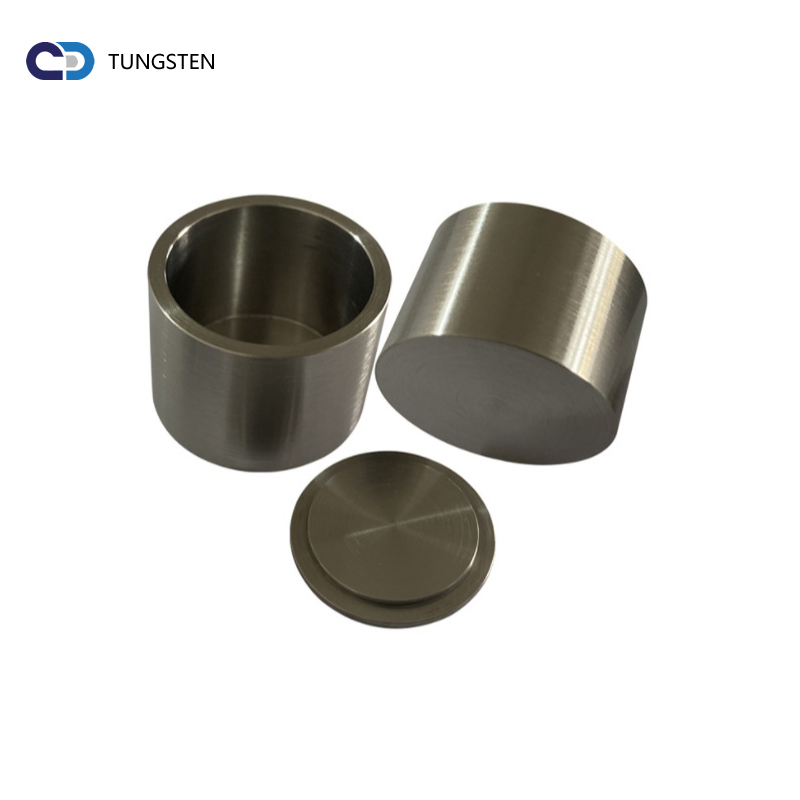

99.95% Purity Pure Tungsten Melting Pot tungsten crucible for sapphire growth furnace components

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Aisea e Filifili ai Matou:

1. E mafai ona e mauaina le mea sili ona lelei e tusa ai ma lou manaʻoga i le tau maualalo.

2. Matou te ofoina atu foʻi Reworks, FOB, CFR, CIF, ma tau tuʻuina atu i le faitotoa. Matou te fautuaina oe e fai fefaʻatauaiga mo felauaiga o le a fai si taugofie.

3. O mea matou te tuʻuina atu e mafai ona faʻamaonia atoatoa, saʻo mai le tusi faʻataʻitaʻiga suʻega mataʻutia i le faʻamatalaga pito mulimuli.

4. faʻamautinoa e tuʻuina atu se tali i totonu ole 24 itula (masani ile itula lava e tasi)

5. E mafai ona e maua isi fa'atauga, fa'atauga fa'atau ma fa'aitiitia le taimi o gaosiga.

6. Matou te faʻamaoni atoatoa ia matou tagata faʻatau. Afai o le a le mafai ona ausia ou manaʻoga pe a uma ona suʻesuʻeina filifiliga uma, matou te le faʻasesēina oe e ala i le faia o folafolaga pepelo e faʻatupuina sootaga lelei tagata faʻatau.

Fa'aaliga falegaosimea

FAAFESOOTAI MATOU

info@zztungsten.com