කාර්මික තාක්ෂණයේ අඛණ්ඩ සංවර්ධනයත් සමඟ නව ද්රව්ය සහ නව ක්රියාවලීන් අඛණ්ඩව මතුවෙමින් පවතී.බකින් බාර්,වැදගත් සම්බන්ධතා මෙවලමක් ලෙස, නව ද්රව්යවල සහ නව ක්රියාවලිවල අවශ්යතා සපුරාලීම සඳහා නිරන්තරයෙන් වැඩිදියුණු කර නවීකරණය කරනු ලැබේ. නිදසුනක් ලෙස, අභ්යවකාශ ක්ෂේත්රයේ සැහැල්ලු සහ ඉහළ ශක්තියේ අවශ්යතා සපුරාලීම සඳහා, ටංස්ටන් මිශ්ර ලෝහ වැනි ඉහළ ක්රියාකාරී ද්රව්ය වලින් සාදන ලද බකින් බාර් සංවර්ධනය කර ඇත. මෙම නව ද්රව්ය යෙදීම අභ්යවකාශ තාක්ෂණයේ දියුණුව ප්රවර්ධනය කර ඇත.

Tungsten Bucking Bar යනු කුමක්ද?

ටංස්ටන් බුක්කිං බාර් යනු වැඩ පෘෂ්ඨ පිටුපසින් ලැබෙන වැඩ මෙවලමක් වන අතර එමඟින් බලපෑම් ගාංචු යෙදීමේදී සහ අතරමැදි මෙවලම් ශීර්ෂය ඇතුළුව සහායක සාමාජිකයෙකු සැපයීම සඳහා අඩු ප්රතිචක්රීකරණ බලපෑම්-අවශෝෂණ ස්පේසර් සහිත කොටස්en සම්පීඩනය සහ කපා හැරීමේදී කම්පන පැටවීම් ලබා ගැනීමට.

අනෙකුත් සම්බන්ධතා මෙවලම් හා සසඳන විට බකින් බාර් වලට පහත වාසි ඇත

වාසි:

1. ඉහළ සම්බන්ධතා ශක්තිය සහ විශ්වසනීයත්වය:

රිවට් කිරීමේ ක්රියාවලියේදී, බකිං බාර් රිවට් පිටුපස ස්ථායී සහ ශක්තිමත් ආධාරකයක් සපයන අතර එමඟින් රිවට් නිවැරදිව විකෘති කර ශක්තිමත් සම්බන්ධතාවයක් ඇති කළ හැකිය. මෙම සම්බන්ධතා ක්රමයට ආතතිය, පීඩනය සහ කැපුම් බලය වැනි විශාල බරකට ඔරොත්තු දිය හැකිය. සමහර මැලියම් සම්බන්ධතා හෝ සරල ෆෙරුල් සම්බන්ධතා සමඟ සසඳන විට, එහි සම්බන්ධතා ශක්තිය සහ විශ්වසනීයත්වය වඩා හොඳ වන අතර, එය ගුවන් යානා බඳ, පාලම්, ගොඩනැගිලි රාමු වැනි ඉහළ සම්බන්ධතා ශක්තිය අවශ්යතා සහිත ව්යුහයන් සඳහා සුදුසු වේ.

දිගු කාලීන භාවිතය හෝ කම්පනය සහ ආතති වෙනස්වීම් වැනි සංකීර්ණ සේවා තත්වයන් යටතේ, බකිං බාර් මගින් සම්බන්ධ කරන ලද ව්යුහය තවමත් හොඳ ස්ථාවරත්වයක් පවත්වා ගත හැකි අතර ලිහිල් වීමට හෝ සම්බන්ධතා අසාර්ථක වීමට ඉඩ නොදේ.

පුළුල් අදාළත්වය:

2. ශක්තිමත් ද්රව්ය අනුවර්තනය වීමේ හැකියාව: විවිධ ද්රව්යවල රිවට් කිරීමට අනුවර්තනය වීමට විවිධ වැඩ අවශ්යතා අනුව විවිධ ද්රව්යවල බකින් බාර් තෝරා ගත හැකිය.

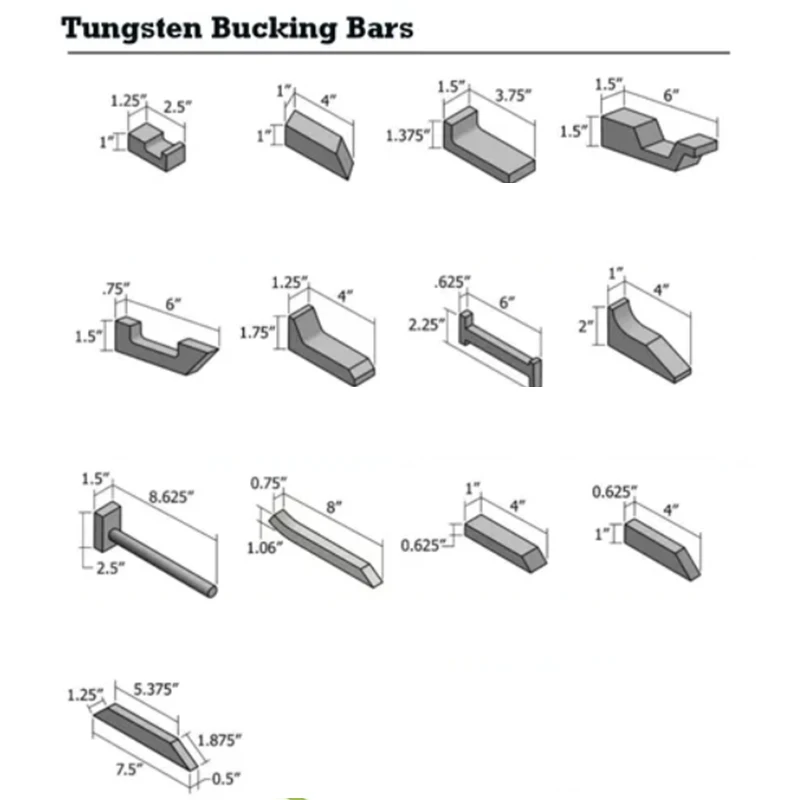

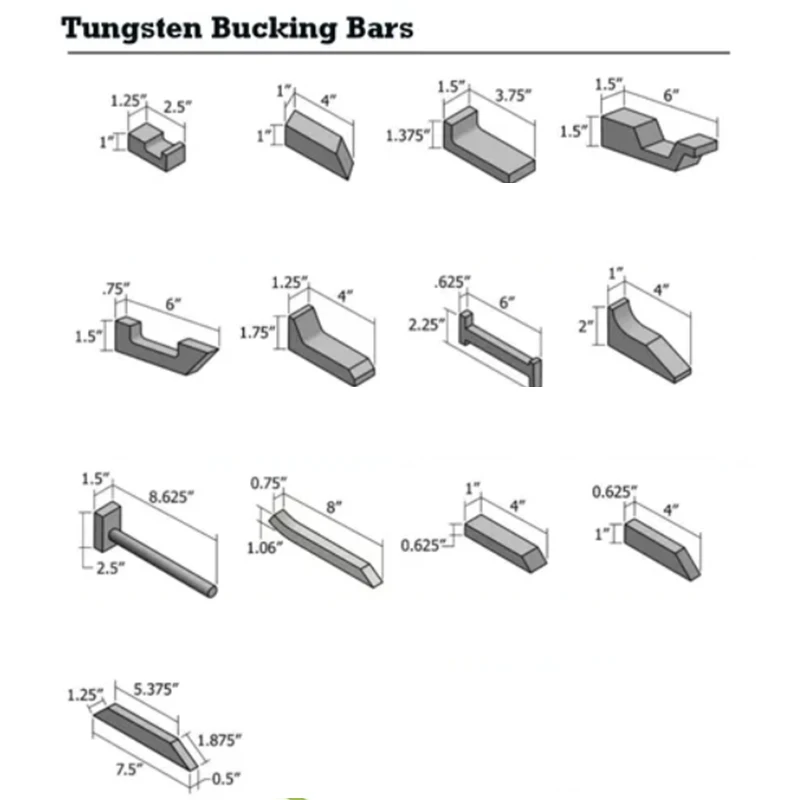

3. සංකීර්ණ ව්යුහයන් සඳහා සුදුසු ය: එහි හැඩය සහ ප්රමාණය නිශ්චිත වැඩ අවස්ථා අනුව සැලසුම් කර අභිරුචිකරණය කළ හැකි අතර, වක්ර පයිප්ප, පටු කුහර, විශේෂ හැඩැති ව්යුහයන් වැනි සංකීර්ණ හැඩයන් සහ පටු අවකාශයන් සහිත ව්යුහවල එය ක්රියාත්මක කළ හැකිය. ., වෙනත් බොහෝ සම්බන්ධතා මෙවලම් සඳහා එය කිරීමට අපහසු වේ.

4. ක්රියා කිරීමට සාපේක්ෂව පහසුය: රිවට් තුවක්කු වැනි මෙවලම් සමඟ ඒකාබද්ධව බකින් බාර් භාවිතා කරන අතර මෙහෙයුම් ක්රියාවලිය සාපේක්ෂව සරල ය.

විවිධ ක්ෂේත්රවල බකිං බාර්වල විශේෂිත යෙදුම් අවස්ථා

1. අභ්යවකාශය

ගුවන් යානා ෆියුස්ලේජ් එකලස් කිරීම: ගුවන් යානා නිෂ්පාදන ක්රියාවලියේදී, බඳෙහි සම සහ රාමුව අතර රිවට් විශාල ප්රමාණයක් අවශ්ය වේ. උදාහරණයක් ලෙස, Boeing 737 සහ Airbus A320 වැනි මගී ගුවන් යානා වල බඳ එකලස් කිරීමේදී, රිවට් සම සහ රාමුව තදින් සම්බන්ධ කිරීම සහතික කිරීම සඳහා බකින් බාර් භාවිතා කරයි.

එන්ජින් සංරචක සම්බන්ධතාවය: ගුවන් යානා එන්ජිම ගුවන් යානයේ මූලික අංගය වන අතර, එය තුළ ඇති සමහර ඉහළ උෂ්ණත්ව සංරචක සහ ව්යුහයන් රිවට් කිරීම මගින් සම්බන්ධ කළ යුතුය. උදාහරණයක් ලෙස, එන්ජින් තලය සහ රෝද හබ් අතර සම්බන්ධතාවය Bucking Bars භාවිතා කිරීමෙන් නිවැරදිව සම්පූර්ණ කළ හැකිය. රිවට් ස්ථාපනය කිරීම තලය රෝද හබ් මත ස්ථාවර ලෙස සවි කිරීමට ඉඩ සලසයි.

2. මෝටර් රථ නිෂ්පාදන ක්ෂේත්රය

ශරීර රාමු එකලස් කිරීම: ඔටෝමොබයිල් බොඩි ෆ්රේම් නිෂ්පාදනයේදී විවිධ හැඩයන් සහ ඝනකම ඇති ලෝහ තහඩු එකට එකතු කිරීම අවශ්ය වේ. උදාහරණයක් ලෙස, කාර් බඳ රාමුව එකලස් කිරීමේ ක්රියාවලියේදී, පැති බාල්ක, හරස් කදම්බ සහ වහල රාමු වැනි සංරචක සම්බන්ධ කිරීම සඳහා බකින් බාර් භාවිතා කරයි. රිය පැදවීමේදී ආතති සහ බලපෑම් බලයට ඔරොත්තු දීමට රිවට් සම්බන්ධතාවයට ප්රමාණවත් ශක්තියක් සැපයිය හැකිය. ඒ අතරම, වෙල්ඩින් සමඟ සසඳන විට, රිවට් කිරීම ශරීරයේ විරූපණය අඩු කර ශරීරයේ එකලස් කිරීමේ නිරවද්යතාව වැඩි දියුණු කළ හැකිය.

කාර් ආසන සවි කිරීම: Riveting ද සාමාන්යයෙන් මෝටර් රථ ආසන සවි කිරීමට භාවිතා කරයි. ආසන බුරුල් නොවන බව සහතික කිරීම සඳහා හදිසි තිරිංග, තියුණු හැරීම් ආදියෙන් ජනනය වන අවස්ථිති බලයට ඔරොත්තු දෙන පරිදි ආසන සවි කිරීමේ රිවට් සවි කිරීම සඳහා බකින් බාර් භාවිතා කරයි.

3. නැව් තැනීමේ ක්ෂේත්රය

හල් කවචය බෙදීම: නැව් තැනීමේදී, හල් කවචය බොහෝ වානේ තහඩු කැබලි මගින් බෙදී ඇත. උදාහරණයක් ලෙස, ටොන් 10,000 භාණ්ඩ නැව් නිෂ්පාදන ක්රියාවලියේදී, වානේ තහඩු කැබලි රිවට් කිරීම මගින් සම්බන්ධ කිරීමට බකින් බාර් භාවිතා කරයි. යාත්රා කිරීමේදී මුහුදු ජලය විඛාදනයට ලක්වීම, තරංග බලපෑම සහ භාණ්ඩ පීඩනය වැනි විවිධ සාධක මගින් නැව්වලට බලපෑම් එල්ල වන බැවින්, මෙම රිවටිං ක්රමය මඟින් බඳෙහි මුද්රා තැබීම සහ ව්යුහාත්මක ශක්තිය සහතික කළ හැකි අතර මුහුදු ජලය බඳ තුළට විනිවිද යාම වළක්වයි.

නැව් අභ්යන්තර ව්යුහය ඉදිකිරීම: නැව තුළ ඇති සමහර කොටස් තොග ශීර්ෂ සහ තට්ටුවේ ආධාරක ව්යුහයන් ද රිවට් කිරීම මගින් ඉදිකර ඇත. මෙම සංකීර්ණ අභ්යන්තර ව්යුහයන් තැනීමේදී රිවට් සවි කිරීම සම්පූර්ණ කිරීමට බකිං බාර් මඟින් උපකාර කළ හැකි අතර, නෞකාවේ අභ්යන්තර ව්යුහය ස්ථිර හා විශ්වාසදායක බවට පත් කිරීම, නෞකාවේ ආරක්ෂිත සංචාලනය සහ භාණ්ඩ ගබඩා කිරීම සඳහා ආරක්ෂාව සපයයි.

4. ඉදිකිරීම් ක්ෂේත්රය

වානේ ව්යුහය ගොඩනැගිලි සම්බන්ධතාවය: විශාල ව්යායාම ශාලා, ප්රදර්ශන ශාලා සහ අනෙකුත් ගොඩනැගිලිවල රාමු ඉදිකිරීම වැනි වානේ ව්යුහ ගොඩනැගිලිවල, වානේ බාල්ක සහ වානේ තීරු වැනි ව්යුහාත්මක සංරචක සම්බන්ධ කිරීම සඳහා බකින් බාර් භාවිතා කරයි. උදාහරණයක් ලෙස, ජාතික ක්රීඩාංගනයේ "කුරුළු කූඩුව" වානේ ව්යුහ රාමුව ඉදිකිරීමේදී, සමහර රිවට් සම්බන්ධතා සඳහා බකින් බාර් භාවිතා කරන ලදී. මෙම සම්බන්ධතා ක්රමය ඔවුන්ගේම බර, සුළං බර, භූමිකම්පා බලවේග ආදියෙහි කොන්දේසි යටතේ වානේ ව්යුහය ගොඩනැගිලිවල ස්ථාවරත්වය සහ ආරක්ෂාව සහතික කළ හැකිය.

තිර බිත්ති සවි කිරීම: ගොඩනැගිලි තිර බිත්ති සවි කිරීම සමහර විට රිවට් කිරීම මගින් ද සිදු කෙරේ. Bucking Bars මගින් තිර බිත්තියේ ලෝහ රාමුව හෝ තහඩුව ගොඩනැගිල්ලේ ප්රධාන ව්යුහයට තදින් සම්බන්ධ කිරීමට උපකාරී වන අතර, විවිධ දේශගුණික තත්ත්වයන් යටතේ (දැඩි සුළං, තද වැසි ආදිය) තිර බිත්තිය ස්ථාවරව පැවතිය හැකි බව සහතික කරයි. වැසි සහ වාතය ඇතුල් වීම වැළැක්වීම සඳහා හොඳ මුද්රා තැබීමක් ඇත.

5. ඉලෙක්ට්රොනික උපකරණ නිෂ්පාදන ක්ෂේත්රය

චැසි ෂෙල් එකලස් කිරීම: සර්වර් චැසිය, පරිගණක චැසිය වැනි ඉලෙක්ට්රොනික උපකරණ චැසි නිෂ්පාදනයේදී චැසි කවච සංරචක සම්බන්ධ කිරීම සඳහා බකින් බාර් භාවිතා කරයි. මෙම චැසි නිශ්චිත විද්යුත් චුම්භක ආවරණ කාර්ය සාධනය සහ යාන්ත්රික ශක්තිය සහතික කිරීමට අවශ්ය වේ. රිවට් කිරීම මගින් විද්යුත් චුම්භක ආවරණයේ අවශ්යතා සපුරාලීම සඳහා කවචය තදින් සම්බන්ධ කළ හැකි අතර, ඒ සමඟම අභ්යන්තර ඉලෙක්ට්රොනික උපාංග ආරක්ෂා කිරීම සඳහා ඇතැම් ගැටුම් සහ පිටකිරීම් වලට ඔරොත්තු දිය හැකිය.

රේඩියේටර් සවි කිරීම: ඉලෙක්ට්රොනික උපකරණවල රේඩියේටරය සාමාන්යයෙන් චිපයේ හෝ වෙනත් උනුසුම් සංරචක මත ස්ථිරව සවි කළ යුතුය. සමහර ඉහළ මට්ටමේ සේවාදායකයන් හෝ කාර්මික පාලන පරිගණකවල, රේඩියේටරය සහ තාපන මූලද්රව්යය අතර හොඳ සම්බන්ධතාවයක් සහතික කිරීම සඳහා රේඩියේටරය සවි කිරීම සඳහා රිවට් ස්ථාපනය සඳහා බකින් බාර් භාවිතා කරයි, එමඟින් තාපය effectively ලදායී ලෙස විසුරුවා හරින අතර අධික උනුසුම් වීම නිසා උපකරණවලට හානි වීම වළක්වයි.

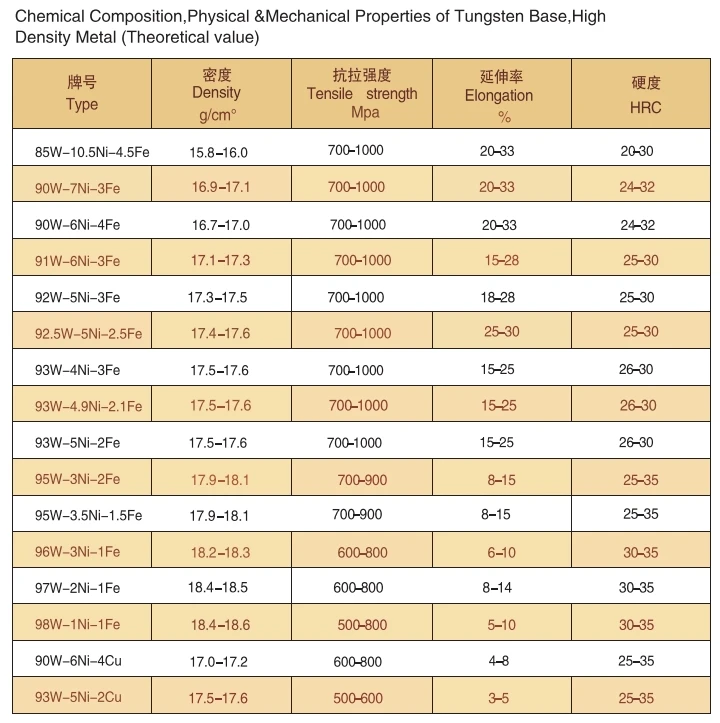

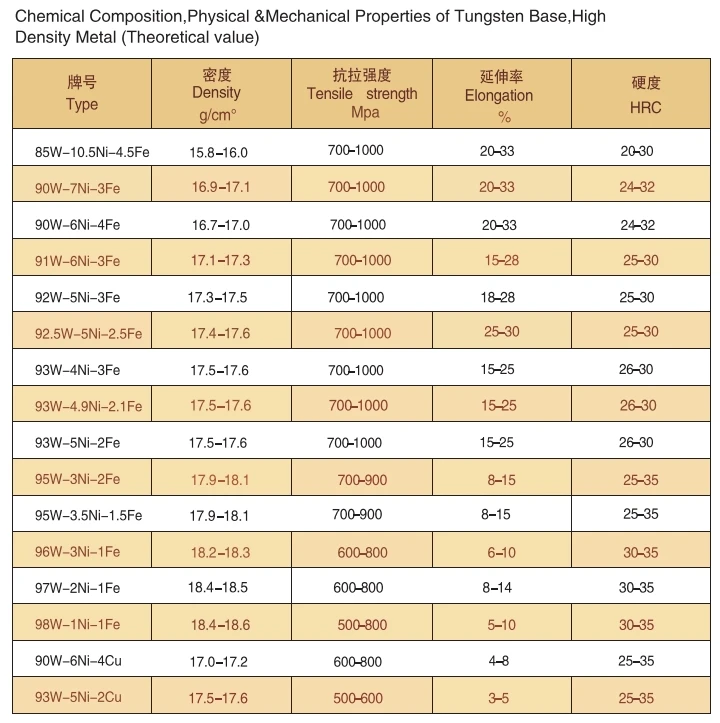

සාරාංශයක් ලෙස, WNiFe ටංස්ටන් මිශ්ර ලෝහ බැකින් බාර් බොහෝ ක්ෂේත්රවල එහි අද්විතීය කාර්යභාරය ඉටු කරයි. බකින් බාර් එකක් තෝරාගැනීමේදී, එහි කාර්ය සාධනය සහ සේවා කාලය සහතික කිරීම සඳහා නිශ්චිත භාවිත අවශ්යතා සහ වැඩ කරන පරිසරය අනුව ඔබ සුදුසු ද්රව්ය ශ්රේණිය තෝරා ගත යුතුය.

අපගේ නිෂ්පාදන සංදර්ශන