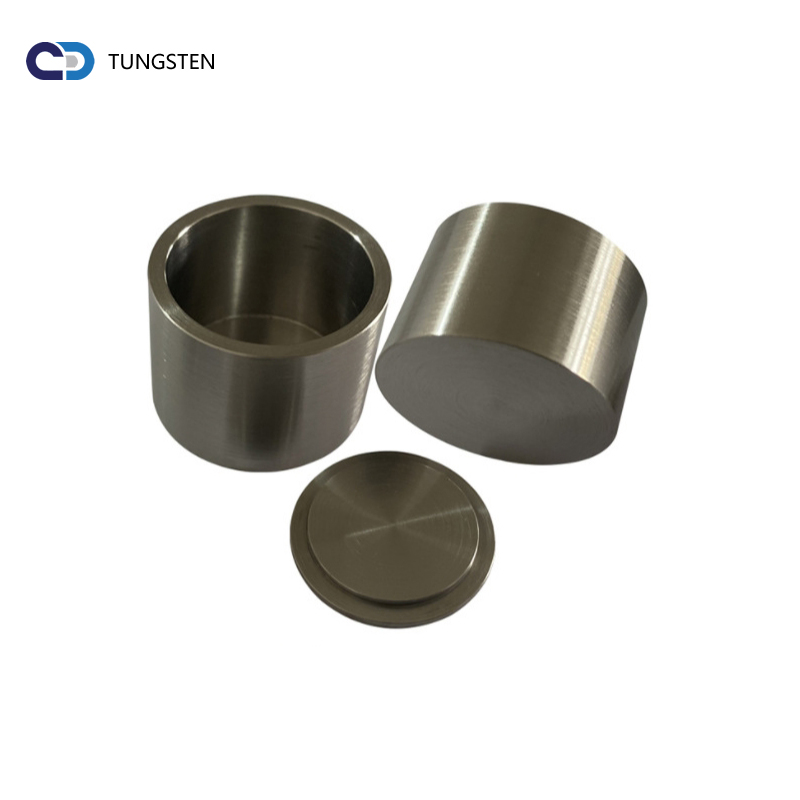

Wholesale High Temperature Sinter Tungsten Melting Crucible for Laboratory

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Kuki Duhitamo:

1. Urashobora kubona ibikoresho byuzuye ukurikije ibyo usabwa byibuze kubiciro bishoboka.

2. Turatanga kandi Reworks, FOB, CFR, CIF, n'inzugi kubiciro byo gutanga inzugi. Turagusaba gukora amasezerano yo kohereza bizaba byubukungu.

3. Ibikoresho dutanga birashobora kugenzurwa rwose, uhereye ku cyemezo cyibizamini fatizo kugeza ku ndunduro yanyuma. (Raporo izerekana kubisabwa)

4. garanti yo gutanga igisubizo mugihe cyamasaha 24 (mubisanzwe mumasaha imwe)

5. Urashobora kubona ubundi buryo bwimigabane, kugemura urusyo hamwe no kugabanya igihe cyo gukora.

6. Twiyeguriye byimazeyo abakiriya bacu. Niba bidashoboka kuzuza ibyo usabwa nyuma yo gusuzuma amahitamo yose, ntituzakuyobya dusezerana ibinyoma bizana umubano mwiza wabakiriya.

Kwerekana uruganda

TWANDIKIRE

info@zztungsten.com