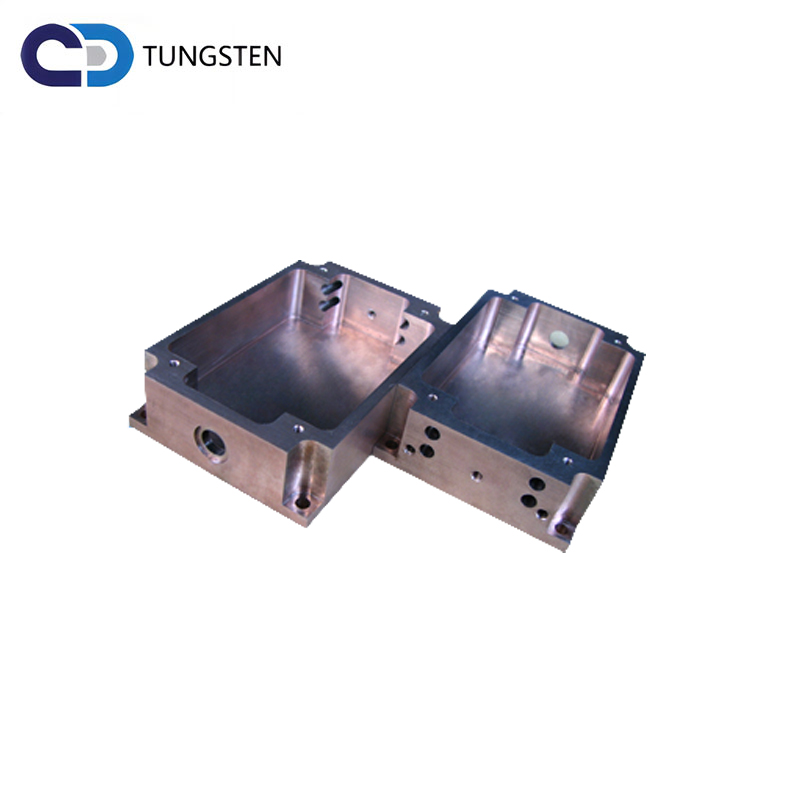

Tungsten mkuwa mbale mbale kufa sanali muyezo mbali

Mafotokozedwe Akatundu

| Zogulitsa | tungsten mkuwa aloyi |

| Zakuthupi | W+Copper+Ni |

| Gulu | W+Copper+Ni |

| Ukulu wa Mbewu | chabwino, chapakati |

| Kuuma | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Pamwamba | opanda kanthu kapena pansi |

| Kugwiritsa ntchito | losindikizidwa kapu kwa transistors kusindikiza chowotcherera, zipangizo contactor kwa masiwichi highvoltage ndi maelekitirodi kwa cheche processing etc. |

Mitundu, kapangidwe ka mankhwala ndi katundu waukulu:

Mtundu | mankhwala opangidwa ndi mkuwa tungsten aloyi (%) | resistivity (cm) | kulimba kwamphamvu (kg/mm2) | kuuma | density(g/cm3) |

W | Cu |

CD1-3 | 60 | bwino | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Brand ndi NO. | Zida za Chemical% | Thupi katundu |

Cu | Zonyansa zonse ≤ | W | Kuchulukana (g/cm³) ≥ | Kuuma HB ≥ | Kukaniza (µΩ·cm) ≤ | Conductivity IACS%≥ | Mphamvu yopindika Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bali. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bali. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bali. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bali. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bali. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Zogulitsa:

1.Kukana kutentha kwabwino

2.Bwino ablate-kukana

3.Kuchulukana kwakukulu

4.Kuthamanga kwambiri

5.Zabwino kwambiri matenthedwe ndi ma electrical conductivity

6.Zosavuta kupanga makina

Zida zathu zonse zimapangidwa ndi atolankhani, sinter, ndikulowa mkati. Aliyense kupangasitepe, kuphatikiza ufa woyambira, imayang'aniridwa, kuyang'aniridwa, ndikusainidwa ndi Quality Assurance. Akamaliza, maere onse opangidwa amawunikidwa ngati ali ndi mphamvu, kachulukidwe, ndi kuuma kwake kusanatumizidwe. Izi zimalembedwa ndikusungidwa pafayilo, komanso zimatsagana ndi magawo kapena zida zikafunsidwa.

EDM ndi ECM

ma tungsten composites amagwiritsidwa ntchito padziko lonse lapansi kwa ma elekitirodi a EDM (Electrical Discharge Machining) ndi ECM (Electrochemical Machining). Zinthu zonse zimapangidwa ndi makina osindikizira, sinter, ndi njira yolowera. Mafuta a Virgin amagwiritsidwa ntchito, zomwe zimapangitsa kuti pakhale zinthu zofananira zomwe zimapereka mitengo yayitali komanso yoyaka. Copper tungsten imagwiritsidwa ntchito popanga plunger/sinker pomwe matanthauzidwe osavuta amafunikira, makamaka mu tungsten carbide.

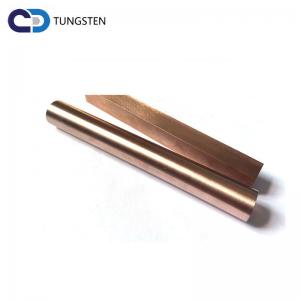

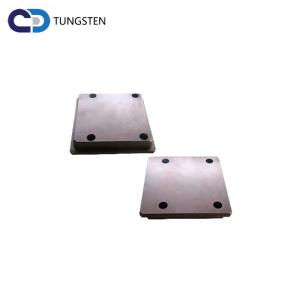

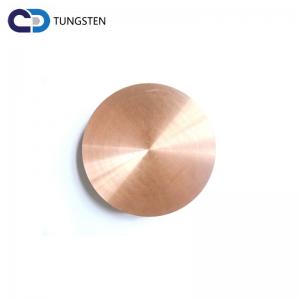

Makulidwe

Mipira: φ 1.5mm -φ 100mm

Shafts: (φ1mm pamwamba) × (Utali max.600mm)

Mapepala: (Kukhuthala 0.15mm pamwamba) × (Kukula max.200mm) × (Utali max.500mm)

Makulidwe akulu, ozungulira komanso akona: m'mimba mwake 550mm pamwamba

Malinga ndi zofuna

Chifukwa Chosankha Ife:

1. Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

2. Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yobweretsera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

3. Zipangizo zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa satifiketi yoyeserera mpaka pagawo lomaliza.

4. chitsimikizo chopereka yankho mkati mwa 24hours (nthawi zambiri mu ola lomwelo)

5. Mutha kupeza njira zina zogulitsira, zoperekera mphero ndikuchepetsa nthawi yopanga.

6. Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

Chiwonetsero cha mafakitale

LUMIKIZANANI NAFE

info@zztungsten.com