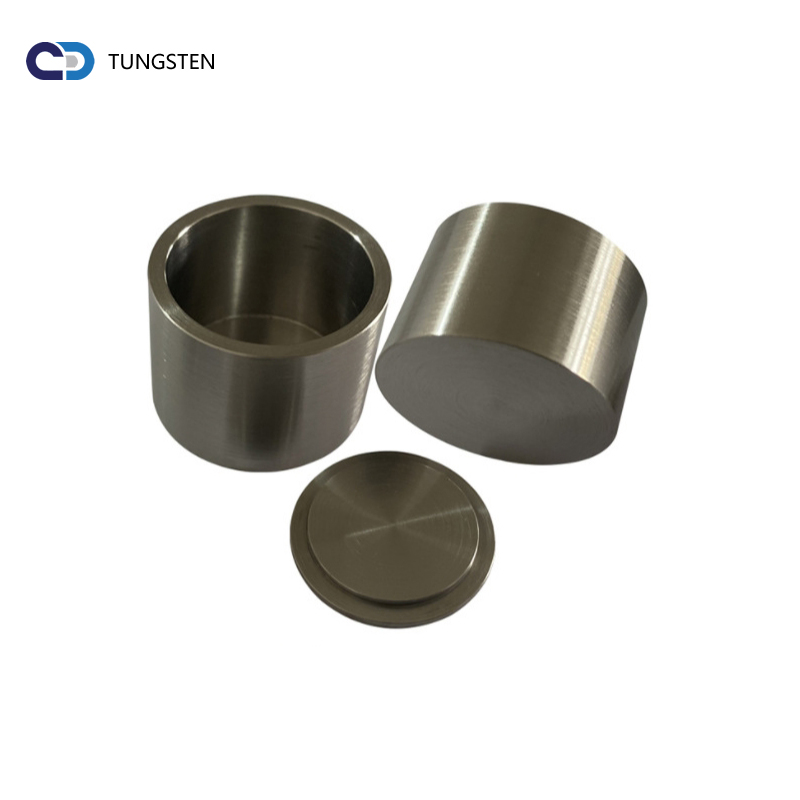

Wholesale High Temperature Sinter Tungsten Melting Crucible for Laboratory

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Nahoana no mifidy anay:

1. Azonao atao ny mahazo ny fitaovana tonga lafatra araka ny takinao amin'ny vidiny faran'izay kely indrindra.

2. Izahay koa dia manolotra Reworks, FOB, CFR, CIF, ary ny vidin'ny fanaterana varavarana. Manoro hevitra anao izahay hanao fifanarahana amin'ny fandefasana entana izay tena ara-toekarena.

3. Ny fitaovana omenay dia azo hamarinina tanteraka, manomboka amin'ny taratasy fanamarinana ara-pitaovana manta ka hatramin'ny fanambarana farany amin'ny lafiny farany.

4. antoka hanome valiny ao anatin'ny 24 ora (matetika amin'ny ora iray ihany)

5. Afaka mahazo tahiry hafa ianao, fanaterana fitotoana miaraka amin'ny fampihenana ny fotoana famokarana.

6. Nanokan-tena tanteraka ho an'ny mpanjifanay izahay. Raha tsy azo atao ny mahafeno ny fepetra takinao rehefa avy nandinika ny safidy rehetra, dia tsy hamitaka anao amin'ny fanaovana fampanantenana diso izay hamorona fifandraisana tsara amin'ny mpanjifa.

Fampisehoana orinasa

MIFANDRAISA AMINAY

info@zztungsten.com