Tungsten ọla kọpa efere anwụ na-abụghị ọkọlọtọ akụkụ

Nkọwa ngwaahịa

| Ngwaahịa | tungsten ọla kọpa alloy |

| Ihe onwunwe | W+Copper+Ni |

| Ọkwa | W+Copper+Ni |

| Nha ọka | mma, ọkara |

| Isi ike | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Elu | oghere ma ọ bụ ala |

| Ngwa | mkpuchi mkpuchi maka transistor sealing welder, ihe kọntaktị maka ọkụ ọkụ dị elu na electrodes maka nhazi ọkụ, wdg. |

Ụdị, ihe mejupụtara kemịkalụ na ihe ndị bụ isi:

Ụdị | Ngwakọta kemịkalụ nke ọla kọpa tungsten alloy (%) | resistivity (cm) | ike tensile (kg/mm2) | isi ike | density(g/cm3) |

W | Cu |

CD1-3 | 60 | itule | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Brand na NO. | Akụkụ kemịkalụ% | Njirimara anụ ahụ |

Cu | Mgbakọta adịghị ọcha ≤ | W | Njupụta (g/cm³) ≥ | Isi ike HB ≥ | Nguzogide (µΩ·cm) ≤ | Omume omume IACS%≥ | Ike na-ehulata Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Njirimara ngwaahịa:

1.Nguzogide okpomọkụ ka mma

2.Mma ablate-eguzogide

3.Nnukwu njupụta

4.Nnukwu ike

5.Ezigbo thermal na electric conductivity

6.Ọ dị mfe iji rụọ ọrụ

A na-emepụta ihe anyị niile site na ndị nta akụkọ, sinter, nainfiltrate usoro. Nke ọ bụla n'ichepụtaUsoro, gụnyere ntụ ntụ bụ isi, bụ nke a na-achịkwa nke ọma, na-enyocha ya ma tinye ya site na Nkwenye Ogo. Mgbe emechara, a na-enyocha nza niile emepụtara maka arụmọrụ, njupụta, na ike tupu ebupu ya. A na-edekọ ma debe ozi a na faịlụ, yana sokwa akụkụ ma ọ bụ akụrụngwa mgbe achọrọ ya.

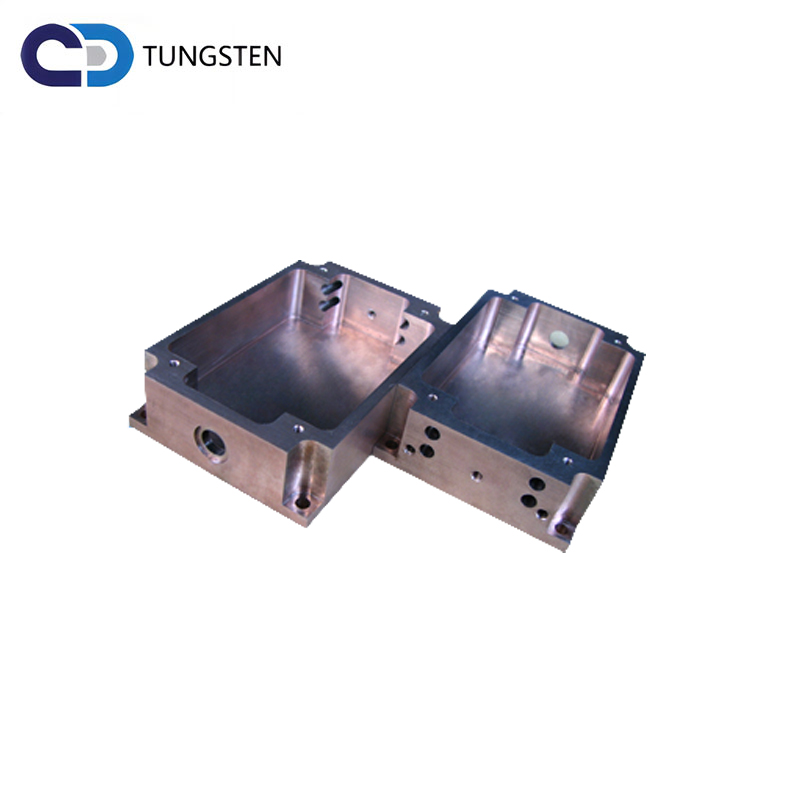

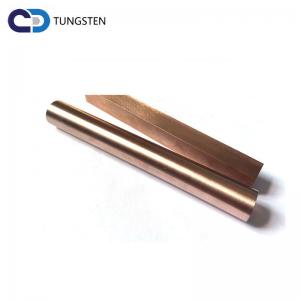

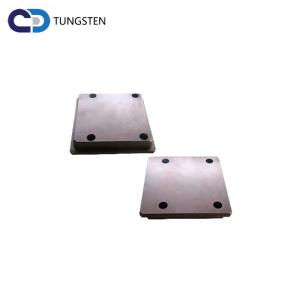

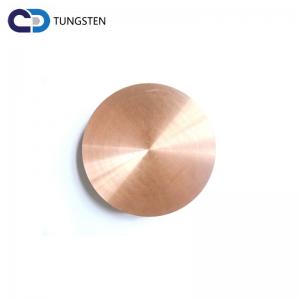

EDM na ECM

A na-eji ihe mejupụtara tungsten gburugburu ụwa maka EDM (Electrical Discharge Machining) na ECM (Electrochemical Machining) electrodes. A na-arụpụta ihe niile site n'ọkpụkpọ nta akụkọ, sinter, na usoro ntinye. A na-eji ntụ ntụ na-amaghị nwoke eme ihe, na-eme ka ihe na-agbanwe agbanwe na-enye ihe dị elu na ọbụna ọkụ ọkụ. A na-eji tungsten ọla kọpa na ngwa plunger/sinker ebe achọrọ nkọwa dị mgbagwoju anya, ọkachasị na tungsten carbide.

Akụkụ

Bọọlụ: φ 1.5mm - φ 100mm

Ogwe: (φ1mm n'elu) × ( Ogologo max.600mm)

Ibé akwụkwọ: (Ọkpụrụkpụ 0.15mm n'elu) × (Wideness max.200mm) × (Length max.500mm)

Mpaghara, okirikiri na akụkụ anọ: dayameta 550mm n'elu

Dị ka a na-achọsi ike

Ihe kpatara ịhọrọ anyị:

1. Ị nwere ike nweta ihe zuru oke dịka ihe ị chọrọ na ọ dịkarịa ala ọnụahịa.

2. Anyị na-enyekwa Reworks, FOB, CFR, CIF, na ọnụ ụzọ nnyefe ọnụ ụzọ. Anyị na-atụ aro ka ịme azụmahịa maka mbupu nke ga-adị oke ọnụ ahịa.

3. Ihe anyị na-enye bụ nkwenye kpamkpam, site na akwụkwọ nyocha nke akụrụngwa ruo na nkwupụta akụkụ ikpeazụ. (Akụkọ ga-egosi na achọrọ)

4. ekwe nkwa inye nzaghachi n'ime awa 24 (na-abụkarị n'otu elekere)

5. Ị nwere ike nweta ngwaahịa ọzọ, igwe ihe nnyefe na ibelata n'ichepụta oge.

6. Anyị raara onwe anyị nye ndị ahịa anyị kpamkpam. Ọ bụrụ na ọ gaghị ekwe omume imezu ihe ndị ị chọrọ mgbe ị nyochachara nhọrọ niile, anyị agaghị eduhie gị site n'ịkwe nkwa ụgha nke ga-eme ka ndị ahịa dị mma.

Ngosipụta ụlọ ọrụ

KPỌTỤRỤ ANYỊ

info@zztungsten.com