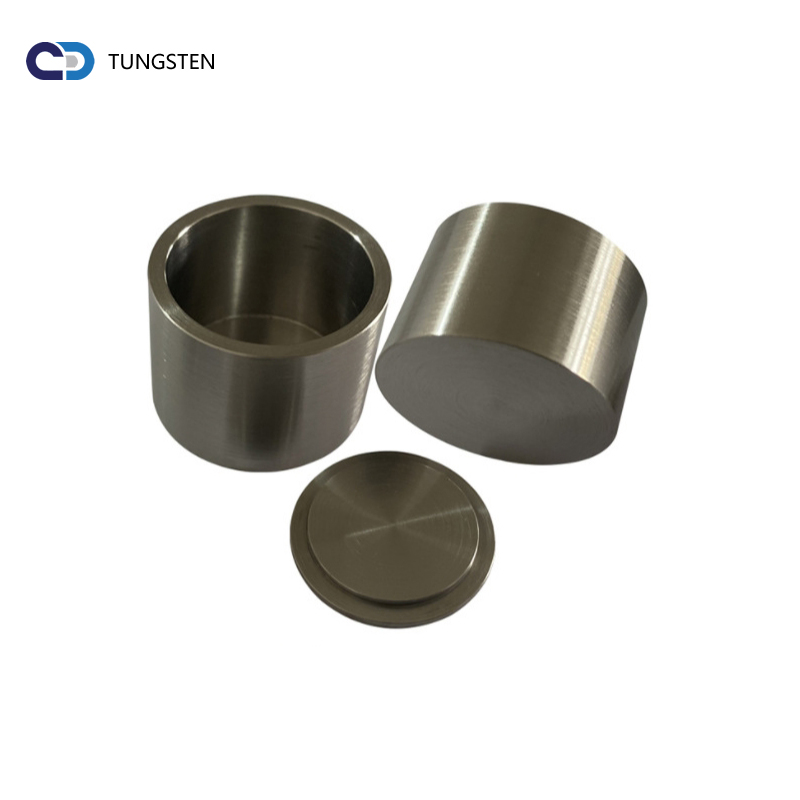

Wholesale High Temperature Sinter Tungsten Melting Crucible for Laboratory

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Ihe kpatara ịhọrọ anyị:

1. Ị nwere ike nweta ihe zuru oke dịka ihe ị chọrọ na ọ dịkarịa ala ọnụahịa.

2. Anyị na-enyekwa Reworks, FOB, CFR, CIF, na ọnụ ụzọ nnyefe ọnụ ụzọ. Anyị na-atụ aro ka ịme azụmahịa maka mbupu nke ga-adị oke ọnụ ahịa.

3. Ihe anyị na-enye bụ nkwenye kpamkpam, site na akwụkwọ nyocha nke akụrụngwa ruo na nkwupụta akụkụ ikpeazụ. (Akụkọ ga-egosi na achọrọ)

4. ekwe nkwa inye nzaghachi n'ime awa 24 (na-abụkarị n'otu elekere)

5. Ị nwere ike nweta ngwaahịa ọzọ, igwe ihe nnyefe na ibelata n'ichepụta oge.

6. Anyị raara onwe anyị nye ndị ahịa anyị kpamkpam. Ọ bụrụ na ọ gaghị ekwe omume imezu ihe ndị ị chọrọ mgbe ị nyochachara nhọrọ niile, anyị agaghị eduhie gị site n'ịkwe nkwa ụgha nke ga-eme ka ndị ahịa dị mma.

Ngosipụta ụlọ ọrụ

KPỌTỤRỤ ANYỊ

info@zztungsten.com