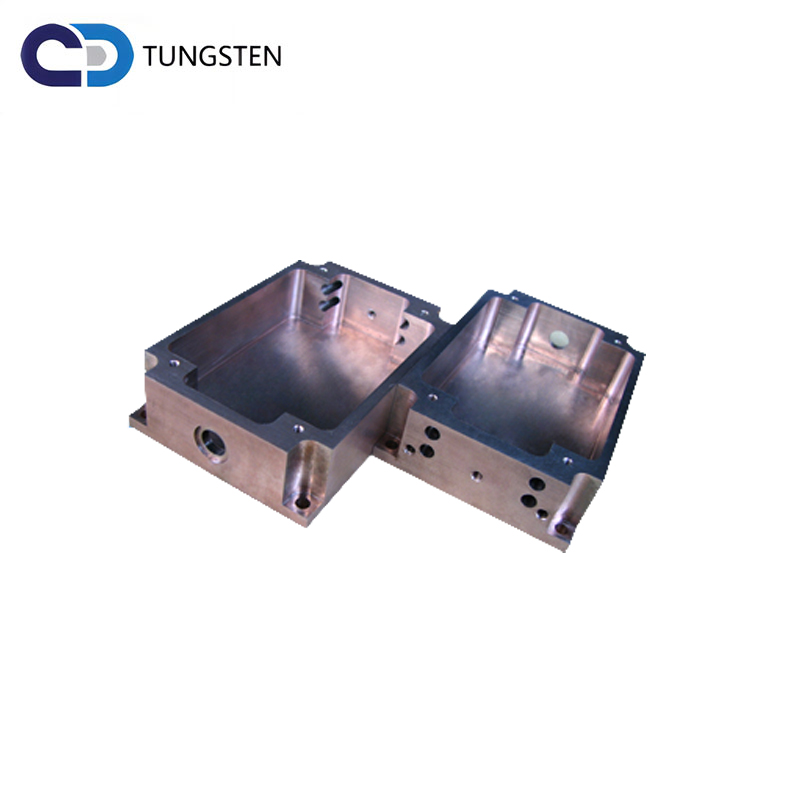

Tungsten tooj liab nkoj phaj tuag uas tsis yog tus qauv

Khoom piav qhia

| Khoom | tungsten tooj liab alloy |

| Khoom siv | W + Copper + Ni |

| Qib | W + Copper + Ni |

| Loj Loj | zoo, medium |

| Hardness | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Nto | dawb los yog hauv av |

| Daim ntawv thov | kaw lub hau rau transistors sealing welder, contactor cov ntaub ntawv rau highvoltage keyboards thiab electrodes rau txim ua thiab lwm yam. |

Hom, tshuaj muaj pes tsawg leeg thiab cov khoom tseem ceeb:

Hom | chemical muaj pes tsawg leeg ntawm tooj liab tungsten alloy (%) | resistivity (cm) | tensile zog (kg / mm2) | tawv | density(g/cm3) |

W | Cu |

CD1-3 | 60 | tshuav nyiaj li cas | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Hom thiab NO. | Chemical Cheebtsam% | Lub cev muaj zog |

Cu | Tag nrho impurities ≤ | W | Qhov ntom (g / cm³) ≥ | Hardness HB ≥ | Kev tiv thaiv (µΩ·cm) ≤ | Kev coj ua IACS% ≥ | Khoov zog Mpa ≥ |

CuW(50) | 50±2.0 | 0.5 | Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

Khoom feature:

1.Ua kom sov zoo dua

2.Zoo dua ablate-tiv taus

3.High density

4.Siab siv

5.Zoo heev thermal thiab electrical conductivity

6.Yooj yim rau machined

Tag nrho peb cov ntaub ntawv yog tsim los ntawm cov xovxwm, sinter, thiabtxheej txheem infiltrate. Txhua qhov kev tsim khoomkauj ruam, suav nrog cov hmoov yooj yim, raug tswj xyuas zoo, saib xyuas, thiab kos npe tawm los ntawm Quality Assurance. Tom qab ua tiav, tag nrho cov khoom tsim tau raug kuaj xyuas cov khoom siv hluav taws xob, qhov ntom ntom, thiab hardness ua ntej xa khoom. Cov ntaub ntawv no raug kaw thiab khaws cia rau hauv cov ntaub ntawv, thiab nrog rau cov khoom lossis cov ntaub ntawv thaum thov.

EDM thiab ECM

tungsten composites yog siv thoob ntiaj teb rau EDM (Electrical Discharge Machining) thiab ECM (Electrochemical Machining) electrodes. Tag nrho cov khoom yog tsim los ntawm cov xovxwm, sinter, thiab infiltrate txheej txheem. Virgin hmoov yog siv, uas ua rau ib tug zoo ib yam li homogeneous khoom muab siab thiab txawm burning nqi. Tooj tungsten yog siv rau hauv plunger / sinker daim ntaub ntawv uas yuav tsum tau intricate txhais, tshwj xeeb tshaj yog nyob rau hauv tungsten carbide.

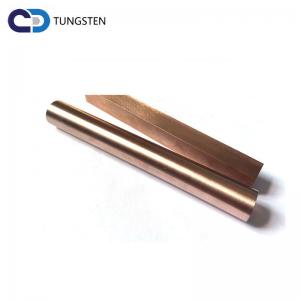

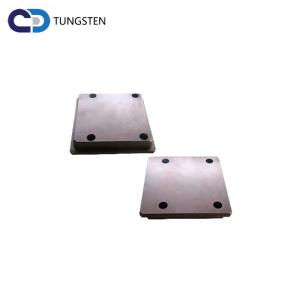

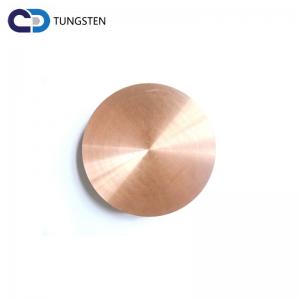

Qhov ntev

Pob: φ1.5mm -φ 100mm

Ncej: (φ1mm saum toj no) × (Length max.600mm)

Cov ntawv: (Thickness 0.15mm saum toj no) × (Wideness max.200mm) × (Length max.500mm)

Square, puag ncig thiab duab plaub qhov ntau thiab tsawg: txoj kab uas hla 550mm saum toj no

Raws li qhov xav tau

Vim li cas thiaj xaiv peb:

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. lav kom muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

Factory zaub

Tiv tauj peb

yog info@zztungsten.com