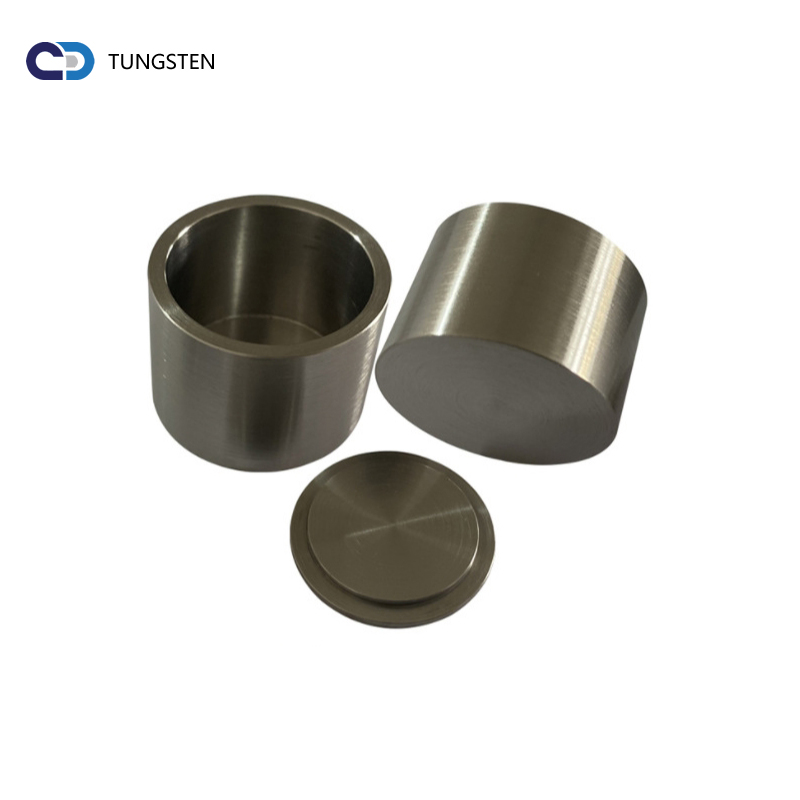

Wholesale High Temperature Sinter Tungsten Melting Crucible for Laboratory

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Vim li cas thiaj xaiv peb:

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. lav kom muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

Factory zaub

Tiv tauj peb

yog info@zztungsten.com