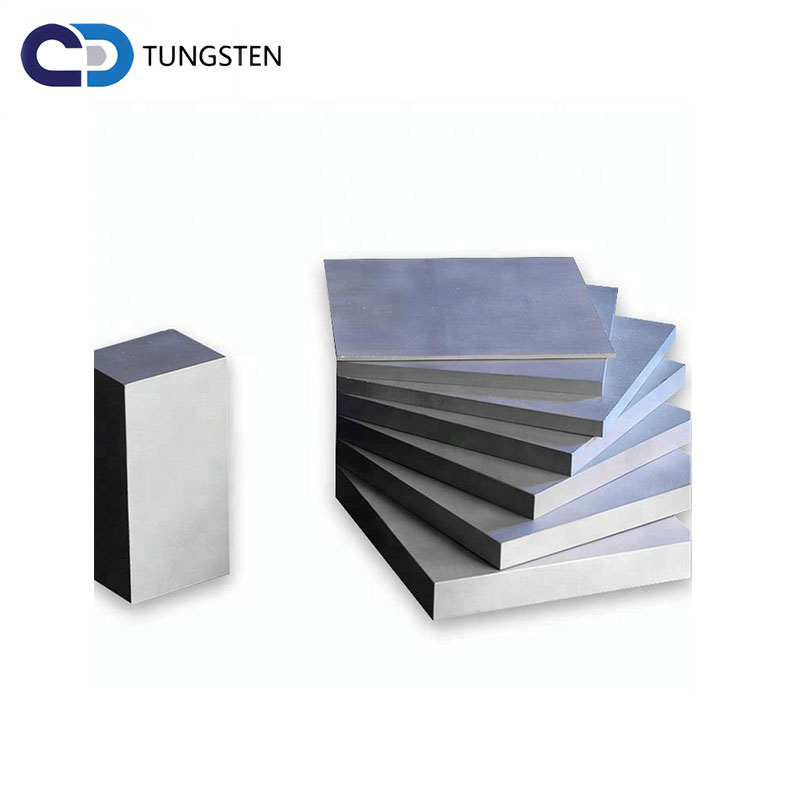

CD Boron Carbide phaj ntawv thaiv Hoobkas nqi

Feature:

Superior hnav tsis kam, cuam tshuam tsis kam thiab corrosion kuj

Zoo heev flatness thiab kub tsis kam mus txog 1380 ℃

Zoo heev oxidation tsis kam

Kev tswj qhov zoo ntawm cov duab zoo

Ib qho yooj yim installation

Lub neej ua haujlwm ntev (li 5 npaug ntau dua li ntawm alumina ceramic thiab 6 npaug ntau dua li ntawm polyurethane)

Daim ntawv thov:

nrog lub zog siab, siab hnav resistantce yog dav siv hauv papermaking, tshuaj, electronics, tshuaj thiab lwm yam inkjet, lithium roj teeb cov ntaub ntawv, hluav taws xob pulp nano-ceramic sanding machines.

CD Boron Carbide phaj ntawv thaiv Hoobkas nqi

| Lub npe | Chav tsev | B4C |

| Qhov ntom | g/cm3 | >2.48 |

| Porosity | % | <0.5 |

| Vickers Hardness | HV1(GPa) | 26 |

| Young's Modulus | GPa | 410 |

| Flexural zog | MPa | 460 |

| Compressive zog | MPa | >2800 |

| Fracture Toughness | MPa 0.5 hli | 5 |

| Coefficient ntawm thermal expansion 25 ℃ -500 ℃ | 10 -6 /K | 4.5 |

| Coefficient ntawm thermal expansion 25 ℃ -500 ℃ | 10 -6 /K | 6.3 |

| 500℃-1000℃ |

|

|

| W/mK | 36 |

| Thermal conductivity ntawm 25 ℃ |

| Ω cm | 1 |

| Kev tiv thaiv hluav taws xob tshwj xeeb ntawm 25 ℃ |

Vim li cas thiaj xaiv peb:

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. lav kom muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

Factory zaub

Tiv tauj peb

yog info@zztungsten.com