Nrog kev txhim kho txuas ntxiv ntawm kev lag luam thev naus laus zis, cov ntaub ntawv tshiab thiab cov txheej txheem tshiab txuas ntxiv mus.Cov Bars,raws li ib qho tseem ceeb ntawm cov cuab yeej sib txuas, kuj tseem niaj hnub txhim kho thiab tsim kho tshiab kom tau raws li cov khoom siv tshiab thiab cov txheej txheem tshiab. Piv txwv li, txhawm rau ua kom tau raws li qhov yuav tsum tau ua ntawm lub teeb yuag thiab lub zog siab hauv thaj chaw aerospace, Bucking Bars ua los ntawm cov khoom siv zoo xws li tungsten alloys tau tsim. Kev siv cov ntaub ntawv tshiab no tau txhawb nqa txoj kev loj hlob ntawm aerospace technology.

Tungsten Bucking Bar yog dab tsi?

Tungsten Buchuab tais bar yog cov cuab yeej ua haujlwm tau txais tom qab qhov chaw ua haujlwm los muab cov tswvcuab txhawb nqa hauv kev siv cov cuab yeej cuam tshuam thiab suav nrog cov cuab yeej cuam tshuam thiab tuav cov khoom nrog qhov qis-recoil cuam tshuam-absorbing spacer muab muaj between coj shock loads nyob rau hauv compression thiab shear.

Bucking Bars muaj qhov zoo hauv qab no piv rau lwm cov cuab yeej txuas

Qhov zoo:

1. Kev sib txuas siab zog thiab kev ntseeg siab:

Thaum lub sij hawm cov txheej txheem riveting, Bucking Bars muab kev txhawb nqa ruaj khov thiab muaj zog nyob rau sab nraum qab ntawm rivet, uas tuaj yeem ua kom raug lub rivet thiab tsim kom muaj kev sib txuas. Txoj kev sib txuas no tuaj yeem tiv taus cov khoom loj xws li nro, siab thiab shear quab yuam. Piv nrog rau qee qhov kev sib txuas ntawm cov kua nplaum los yog kev sib txuas yooj yim ferrule, nws qhov kev sib txuas muaj zog thiab kev ntseeg tau zoo dua, thiab nws yog qhov tsim nyog rau cov qauv uas muaj kev sib txuas siab, xws li cov dav hlau fuselages, txuas hniav, lub tsev thav duab, thiab lwm yam.

Raws li kev siv mus ntev lossis kev ua haujlwm nyuaj xws li kev vibration thiab kev ntxhov siab hloov pauv, cov qauv txuas nrog Bucking Bars tseem tuaj yeem ua kom muaj kev ruaj ntseg zoo thiab tsis yooj yim rau loosening lossis txuas tsis ua haujlwm.

Kev siv dav dav:

2. Cov ntaub ntawv muaj zog adaptability: Bucking Bars ntawm cov khoom sib txawv tuaj yeem xaiv raws li kev ua haujlwm sib txawv yuav tsum tau hloov mus rau riveting ntawm ntau yam ntaub ntawv.

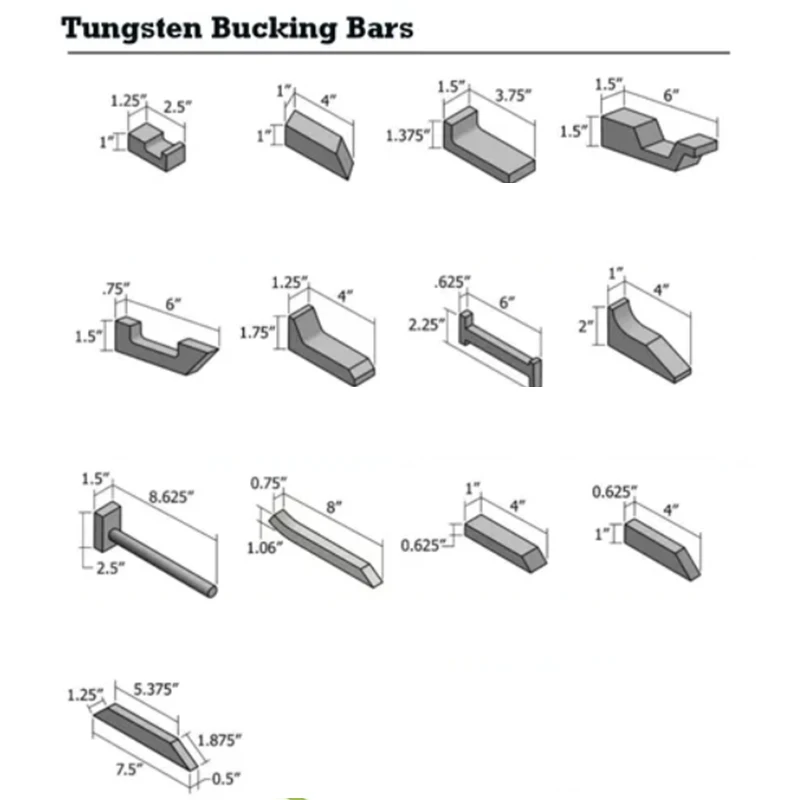

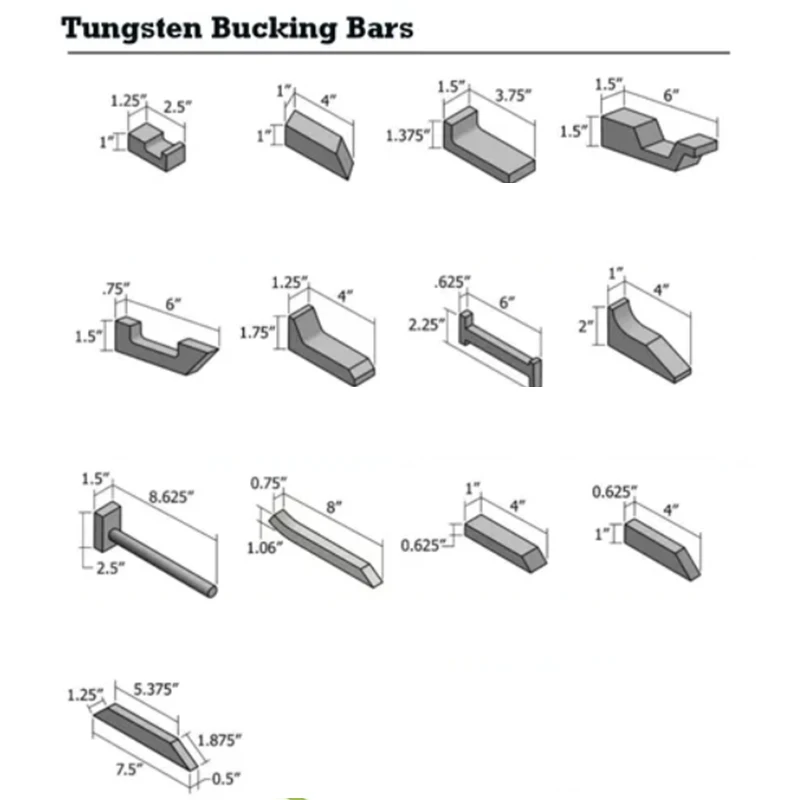

3. Haum rau cov txheej txheem nyuaj: Nws cov duab thiab qhov loj tuaj yeem tsim thiab kho raws li cov xwm txheej ua haujlwm tshwj xeeb, thiab nws tuaj yeem ua haujlwm hauv cov qauv nrog cov duab nyuaj thiab qhov chaw nqaim, xws li cov kav dej nkhaus, nqaim kab noj hniav, cov qauv tsim tshwj xeeb, thiab lwm yam. ., uas yog qhov nyuaj rau ntau lwm yam kev sib txuas ua ke.

4. Yooj yim rau kev khiav lag luam: Bucking Bars yog siv ua ke nrog cov cuab yeej xws li phom rivet, thiab cov txheej txheem ua haujlwm yog qhov yooj yim.

Daim ntawv thov tshwj xeeb ntawm Bucking Bars hauv ntau qhov chaw

1. Aerospace

Aircraft fuselage los ua ke: Thaum lub sij hawm tsim cov txheej txheem dav hlau, ntau tus riveting yuav tsum tau nruab nrab ntawm daim tawv nqaij fuselage thiab tus ncej. Piv txwv li, nyob rau hauv lub fuselage sib dhos ntawm cov neeg nrog caij dav hlau xws li Boeing 737 thiab Airbus A320, Bucking Bars yog siv los xyuas kom meej tias cov rivets nruj nreem txuas ntawm daim tawv nqaij thiab ncej.

Cav qhov sib txuas: Lub cav dav hlau yog lub hauv paus tseem ceeb ntawm lub dav hlau, thiab qee qhov kub-kub thiab cov qauv hauv nws kuj yuav tsum tau txuas nrog riveting. Piv txwv li, kev sib txuas ntawm lub cav hniav thiab lub log hub tuaj yeem ua tiav los ntawm kev siv Bucking Bars. Lub installation ntawm rivets tso cai rau cov hniav kom ruaj khov ntawm lub log hub.

2. Automotive manufacturing teb

Lub cev ncej sib dhos: Hauv kev tsim cov tsheb lub cev thav ntawv, cov ntawv hlau ntawm cov duab sib txawv thiab cov tuab yuav tsum tau sib txuas ua ke. Piv txwv li, nyob rau hauv cov txheej txheem sib dhos ntawm lub tsheb lub cev ncej, Bucking Bars yog siv los txuas cov khoom xws li sab kab teeb, hla kab thiab ru tsev thav ntawv. Riveted kev sib txuas tuaj yeem muab lub zog txaus los tiv thaiv torsion thiab cuam tshuam lub zog thaum tsav tsheb. Nyob rau tib lub sijhawm, piv nrog vuam, riveting tuaj yeem txo qhov deformation ntawm lub cev thiab txhim kho qhov tseeb ntawm lub cev.

Kev teeb tsa lub tsheb: Riveting feem ntau yog siv los kho cov rooj zaum hauv tsheb. Bucking Bars yog siv los txhim kho lub rooj zaum kho rivets kom cov rooj zaum tuaj yeem tiv taus lub zog inertial tsim los ntawm kev nres nres, ntse tig, thiab lwm yam, kom ntseeg tau tias cov rooj zaum yuav tsis xoob.

3. Shipbuilding teb

Lub plhaub splicing: Hauv kev tsim nkoj, lub plhaub plhaub yog spliced los ntawm ntau daim hlau phaj. Piv txwv li, hauv cov txheej txheem tsim khoom ntawm 10,000-tuj cov nkoj thauj khoom, Bucking Bars yog siv los txuas cov hlau phaj los ntawm riveting. Txij li thaum cov nkoj raug cuam tshuam los ntawm ntau yam xws li seawater corrosion, yoj cuam tshuam thiab cov khoom thauj siab thaum lub sij hawm navigation, txoj kev riveting no tuaj yeem ua kom lub sealing thiab lub zog ntawm lub nkoj thiab tiv thaiv dej hiav txwv los ntawm kev nkag mus rau hauv lub nkoj.

Nkoj sab hauv kev tsim kho: Qee qhov kev faib tawm bulkheads thiab lawj kev txhawb nqa cov qauv hauv lub nkoj kuj tau tsim los ntawm riveting. Bucking Bars tuaj yeem pab ua kom tiav kev teeb tsa ntawm rivets hauv kev tsim kho ntawm cov txheej txheem sab hauv, ua rau cov qauv sab hauv ntawm lub nkoj ruaj khov thiab txhim khu kev qha, muab kev tiv thaiv kev nyab xeeb ntawm lub nkoj thiab kev cia khoom.

4. Kev tsim kho thaj chaw

Steel qauv tsev sib txuas: Nyob rau hauv steel qauv vaj tse, xws li cov thav duab kev tsim kho ntawm loj gymnasiums, exhibition halls thiab lwm lub tsev, Bucking Bars yog siv los txuas cov txheej txheem xws li steel beams thiab steel kem. Piv txwv li, thaum lub sij hawm tsim cov steel qauv ncej ntawm National Stadium "Bird's Zes", Bucking Bars tau siv rau qee qhov kev sib txuas rivet. Txoj kev sib txuas no tuaj yeem ua kom muaj kev ruaj ntseg thiab kev nyab xeeb ntawm steel qauv vaj tse nyob rau hauv cov xwm txheej ntawm lawv tus kheej qhov hnyav, cua loads, av qeeg rog, thiab lwm yam.

Kab hlau rhuav phab ntsa installation: Lub installation ntawm lub tsev kab hlau rhuav phab ntsa yog qee zaum kuj ua los ntawm riveting. Bucking Bars tuaj yeem pab txuas cov hlau ncej lossis phaj ntawm cov ntaub thaiv phab ntsa rau cov qauv tseem ceeb ntawm lub tsev, kom ntseeg tau tias cov ntaub thaiv phab ntsa tuaj yeem nyob ruaj khov nyob rau hauv ntau yam kev nyab xeeb (xws li cua daj cua dub, nag hnyav, thiab lwm yam), thiab muaj zoo sealing los tiv thaiv los nag thiab cua infiltration.

5. Cov khoom siv hluav taws xob tsim khoom lag luam

Chassis plhaub sib dhos: Hauv kev tsim cov khoom siv hluav taws xob chassis, xws li server chassis, computer chassis, thiab lwm yam, Bucking Bars yog siv los txuas cov chassis plhaub Cheebtsam. Cov chassis no yuav tsum tau ua kom ntseeg tau qee yam electromagnetic shielding kev ua tau zoo thiab txhua yam muaj zog. Riveting tuaj yeem ua rau lub plhaub nruj kom ua tau raws li qhov yuav tsum tau muaj ntawm electromagnetic shielding, thiab tib lub sijhawm tuaj yeem tiv taus qee qhov kev sib tsoo thiab extrusion los tiv thaiv cov khoom siv hluav taws xob sab hauv.

Radiator kho: Lub tshuab hluav taws xob ntawm cov khoom siv hluav taws xob feem ntau yuav tsum tau kho kom ruaj khov ntawm cov nti lossis lwm yam khoom siv cua sov. Hauv qee qhov high-end servers lossis cov khoos phis tawj tswj kev lag luam, Bucking Bars yog siv rau kev teeb tsa rivet los txhim kho lub tshuab hluav taws xob kom ntseeg tau tias muaj kev sib cuag zoo ntawm lub tshuab hluav taws xob thiab cov cua sov, yog li ua kom muaj cua sov thiab tiv thaiv cov cuab yeej los ntawm kev puas tsuaj vim overheating.

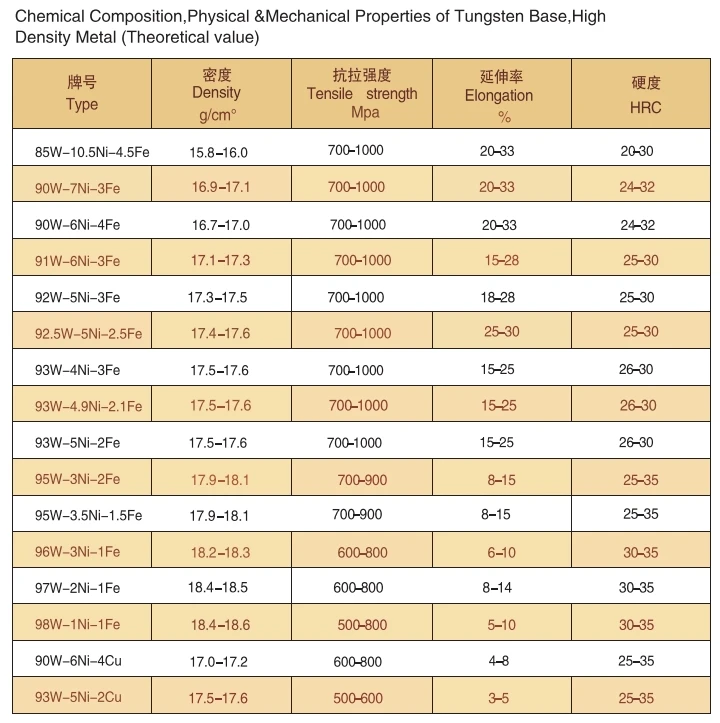

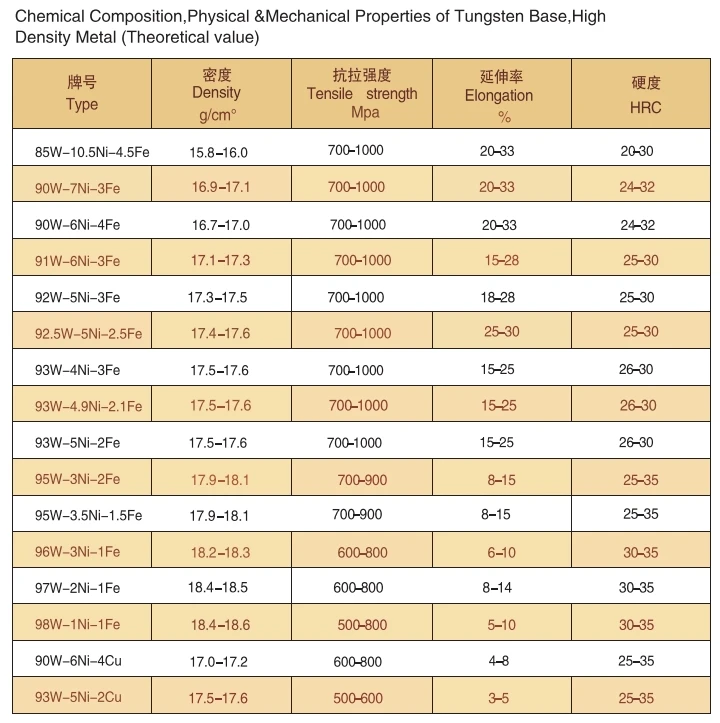

Hauv cov ntsiab lus, WNiFe tungsten alloy bucking bar plays nws lub luag haujlwm tshwj xeeb hauv ntau qhov chaw. Thaum xaiv ib lub bucking bar, koj yuav tsum xaiv cov khoom tsim nyog raws li kev siv tshwj xeeb thiab ib puag ncig ua haujlwm kom ntseeg tau tias nws ua tau zoo thiab kev pabcuam lub neej.

Peb Cov Khoom Muag Khoom Muag