ʻO ka pā moku moku Tungsten e make nā ʻāpana maʻamau

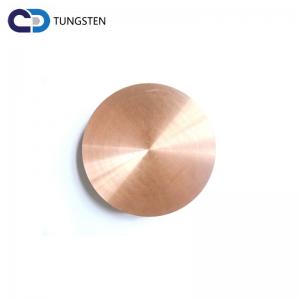

wehewehe huahana

| Huahana | tungsten keleawe huila |

| Mea waiwai | W+Copper+Ni |

| Papa | W+Copper+Ni |

| Ka nui o ka palaoa | maikaʻi, waena |

| ʻoʻoleʻa | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Ili | hakahaka a lepo paha |

| Palapala noi | ka pāpale i hoʻopaʻa ʻia no ka transistors sealing welder, nā mea hoʻopili no nā hoʻololi kiʻekiʻe a me nā electrodes no ka hoʻoili ʻana i ka spark etc. |

Nā ʻano, nā haku mele a me nā waiwai nui:

ʻAno | ka hui kemika o ke keleawe tungsten alloy(%) | kū'ē (cm) | ikaika uʻi (kg/mm2) | paakiki | density(g/cm3) |

W | Cu |

CD1-3 | 60 | kaulike | <=3.26*10-6 | >=130 | >=160 | >=12.70 |

70 | <=3.80*10-6 |

| >=200 | >=13.80 |

80 | <=4.00*10-6 |

| >=220 | >=15.00 |

Brand a me NO. | Nā ʻāpana kemikala% | Nā waiwai kino |

Cu | Huina haumia ≤ | W | ʻO ka mānoanoa (g/cm³) ≥ | ʻoʻoleʻa HB ≥ | Kū'ē (µΩ·cm) ≤ | ʻO ka hoʻokō IACS%≥ | Ka ikaika kulou Mpa≥ |

CuW(50) | 50±2.0 | 0.5 | ʻO Bal. | 11.85 | 115 | 3.2 | 54 |

|

CuW(55) | 45±2.0 | 0.5 | ʻO Bal. | 12.30 | 125 | 3.5 | 49 |

|

CuW(60) | 40±2.0 | 0.5 | ʻO Bal. | 12.75 | 140 | 3.7 | 47 |

|

CuW(65) | 35±2.0 | 0.5 | ʻO Bal. | 13.30 | 155 | 3.9 | 44 |

|

CuW(70) | 30±2.0 | 0.5 | ʻO Bal. | 13.80 | 175 | 4.1 | 42 | 790 |

CuW(75) |

|

|

|

|

|

|

|

|

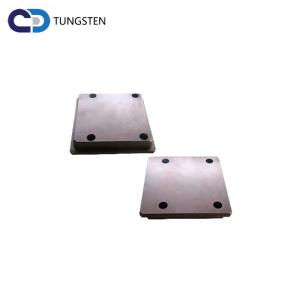

Hiʻona huahana:

1.ʻOi aku ka maikaʻi o ka pale wela

2.ʻOi aku ka maikaʻi ablate-kū'ē

3.Kiʻekiʻe kiʻekiʻe

4.Ka ikaika kiʻekiʻe

5.Maikaʻi ka wela a me ka elctrical conductivity

6.E maʻalahi ka mīkini

Hoʻokumu ʻia kā mākou mau mea āpau e ka paʻi, sinter, akaʻina hana infiltrate. ʻO kēlā me kēia hanaʻO ka step, me ka pauka kumu, ka mālama pono ʻia, nānā ʻia, a kau inoa ʻia e ka Quality Assurance. Ma hope o ka pau ʻana, nānā ʻia nā ʻāpana hana a pau no ka conductivity, density, a me ka paʻakikī ma mua o ka hoʻouna ʻana. Hoʻopaʻa ʻia kēia ʻike a mālama ʻia ma ka faila, a hele pū me nā ʻāpana a i ʻole nā mea i noi ʻia.

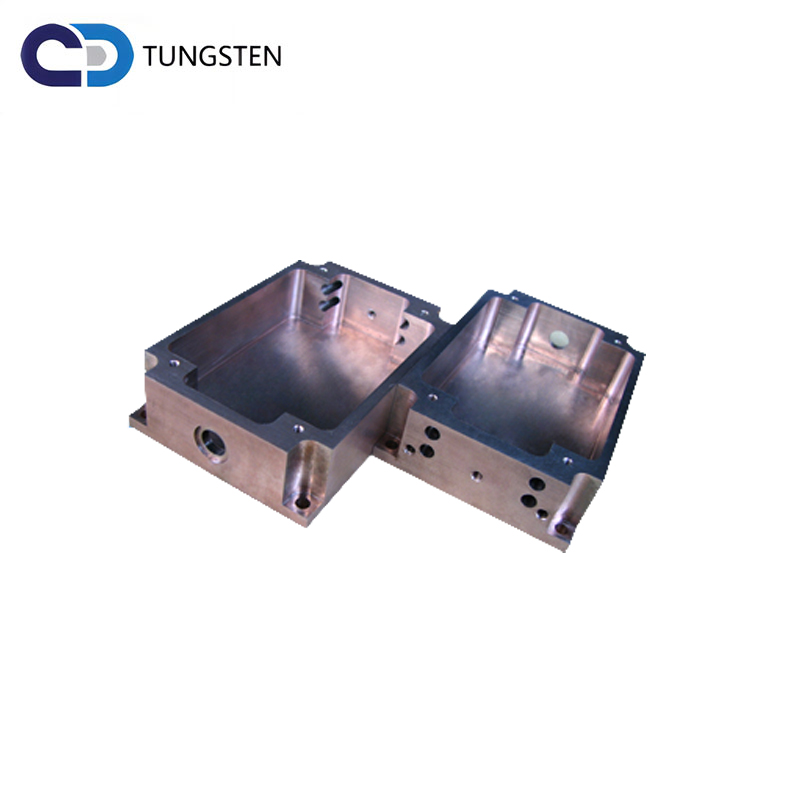

EDM a me ECM

Hoʻohana ʻia nā tungsten composites ma ka honua holoʻokoʻa no ka EDM (Electrical Discharge Machining) a me ECM (Electrochemical Machining) electrodes. Hana ʻia nā mea āpau e ka paʻi, sinter, a me ke kaʻina infiltrate. Hoʻohana ʻia nā pauka wahine, ka hopena i kahi mea like like me ka hāʻawi ʻana i nā helu kiʻekiʻe a me ke ahi. Hoʻohana ʻia ka tungsten keleawe i nā noi plunger/sinker kahi e koi ʻia ai ka wehewehe paʻakikī, ʻoi aku hoʻi i ka tungsten carbide.

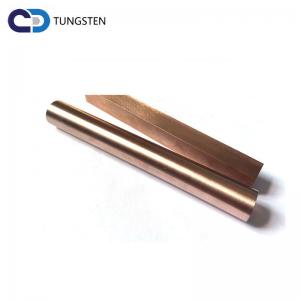

Anana

Nā pōlele: φ 1.5mm -φ 100mm

Nā kumu: (φ1mm ma luna)×(Length max.600mm)

Pepa: (0.15mm mānoanoa ma luna)×(Ka laulā max.200mm)×(Ka lōʻihi max.500mm)

Ka huinaha, poepoe a me ka huinahalike: anawaena 550mm maluna

E like me ke koi

No ke aha e koho ai iā mākou:

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i nā hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi nei ua hiki ke hōʻoia ʻia, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope loa. (E hōʻike ʻia nā hōʻike ma ke koi)

4. hōʻoia e hāʻawi i ka pane i loko o 24hours (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

Hōʻike hale hana

KĀHEA IĀ MĀ˚OU

info@zztungsten.com