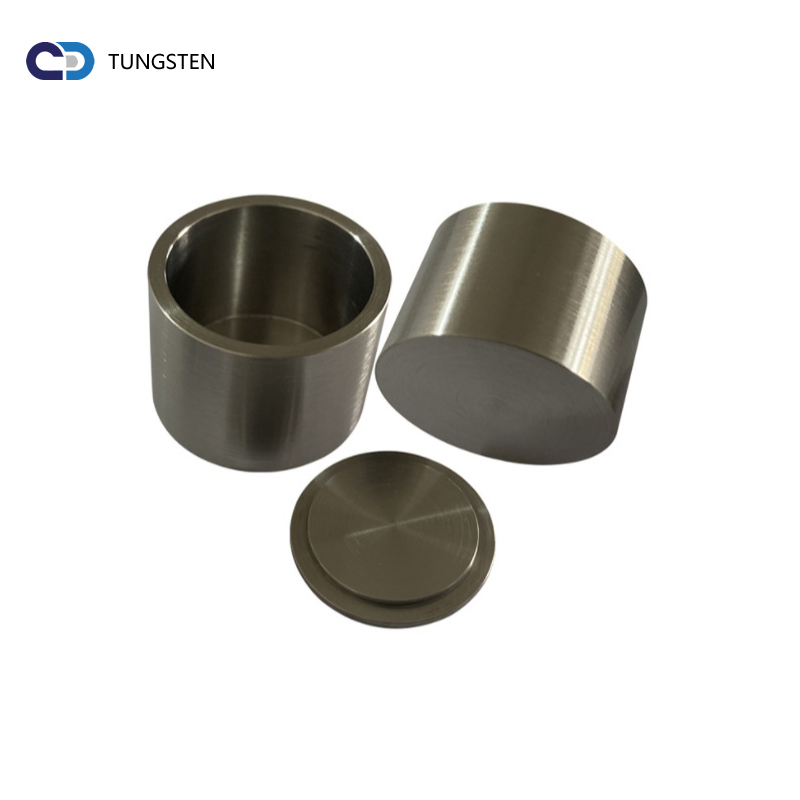

99.95% Purity Pure Tungsten Melting Pot tungsten crucible for sapphire growth furnace components

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

No ke aha e koho ai iā mākou:

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i nā hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi nei ua hiki ke hōʻoia ʻia, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope loa. (E hōʻike ʻia nā hōʻike ma ke koi)

4. hōʻoia e hāʻawi i ka pane i loko o 24hours (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

Hōʻike hale hana

KĀHEA IĀ MĀ˚OU

info@zztungsten.com