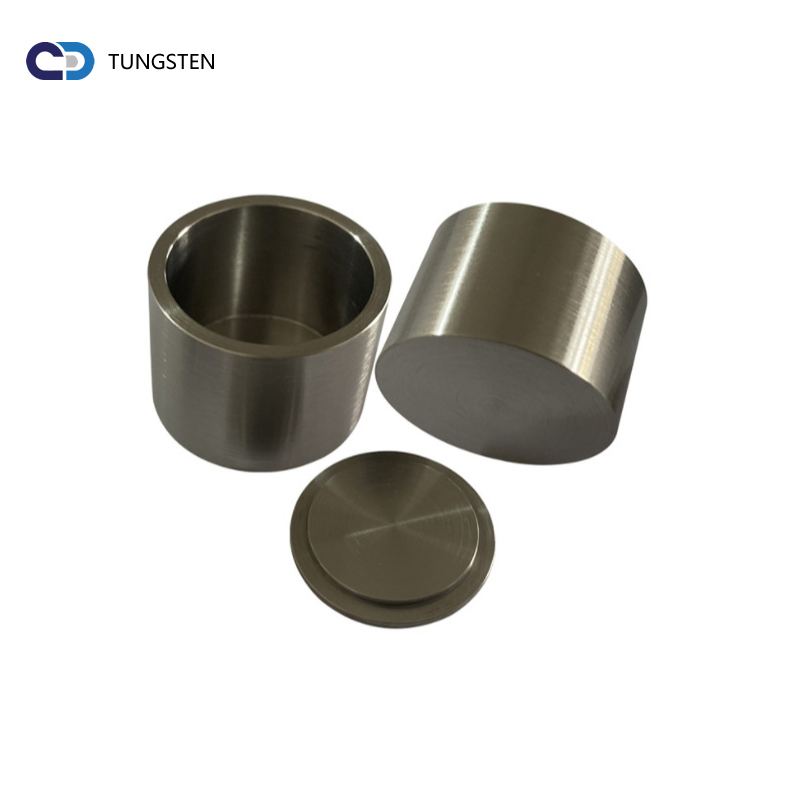

99.95% Purity Pure Tungsten Melting Pot tungsten crucible for sapphire growth furnace components

| Item name | w1 pure tungsten smelting crucible / tungsten forging crucible / tungsten melting pot / tungsten crucible tungsten pot tungsten cup |

| Purity | 99.95% Pure tungsten |

| MOQ | 1pc |

| Working temperature | 1800-2600℃ |

| Processing | Sintering, Forging, machining |

| Other material | molybdenum crucible tantalum crucible |

| niobium crucible nickel crucible |

| Density | 1.Sintering tungsten crucible: 18-18.5g/cm3 |

| 2.Forging tungsten crucible : 18.5-19.2g/cm3 |

| Dimension | We can accept customized according to your drawing. |

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | inner surface finish | inner bottom finish |

| 30-50 | 2-10 | ≤200 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50-100 | 3-15 | ≤300 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100-150 | 3-15 | ≤350 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150-200 | 5-20 | ≤400 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200-300 | 8-25 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300-400 | 8-30 | ≤600 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400-450 | 8-30 | ≤650 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450-600 | 8-35 | ≤800 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

General information of tungsten crucible

Feature:

* High density

* Good corrosion resistance

* The surface roughness of tooled crucibles does not exceed Rz 6.3

* The use temperature below 2600ºC in vacuum or deoxidize atmosphere

* Manufactured based on customers' requirement

Advantages of product:

1. High thermal conductivity

2. High thermal expansion coefficient

3. Great strength under high temperature

4. Anti-friction corrosion resistance

5. Good harden ability.

Application:

* Used for sapphire single crystal growth furnace;

* Applied for quartz glass melting furnace;

* Used for rare earth smelting furnace;

* Used for sintering metal mold of high melting point;

* Widely used in other following industries: Ceramics and metallurgical industries, machinery processing and light industries.

Specifications

1.According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming.

2.Turning forming is mainly applied. We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.

3.We can produce tungsten crucible for vacuum coating according to the customer drawing.

Me yasa Zaba Mu:

1. Kuna iya samun cikakkiyar kayan aiki bisa ga buƙatun ku aƙalla farashin mai yiwuwa.

2. Har ila yau, muna ba da Reworks, FOB, CFR, CIF, da ƙofar zuwa farashin bayarwa. Muna ba ku shawarar yin ciniki don jigilar kaya wanda zai zama mai fa'ida sosai.

3. Abubuwan da muke samarwa suna da tabbaci gaba ɗaya, tun daga takardar shaidar gwajin albarkatun ƙasa zuwa bayanin ƙimar ƙarshe. (Rahotanni za su nuna akan buƙata)

4. garantin bayar da amsa a cikin sa'o'i 24 (yawanci a cikin sa'a guda)

5. Kuna iya samun madadin hannun jari, isar da niƙa tare da rage lokacin masana'antu.

6. Muna da cikakkiyar sadaukarwa ga abokan cinikinmu. Idan ba zai yiwu ba don biyan bukatun ku bayan nazarin duk zaɓuɓɓuka, ba za mu ɓatar da ku ta hanyar yin alkawuran ƙarya wanda zai haifar da kyakkyawar dangantakar abokan ciniki.

Nunin masana'anta

TUNTUBE MU

info@zztungsten.com