Tare da ci gaba da ci gaba da fasahar masana'antu, sababbin kayan aiki da sababbin matakai suna ci gaba da fitowa.Bucking Bars,a matsayin kayan aiki mai mahimmanci na haɗin gwiwa, ana kuma inganta su akai-akai kuma ana sabunta su don saduwa da bukatun sababbin kayan aiki da sababbin matakai. Alal misali, don saduwa da buƙatun nauyi da ƙarfin ƙarfi a cikin filin sararin samaniya, Bucking Bars da aka yi da kayan aiki masu mahimmanci irin su tungsten gami an haɓaka su. Yin amfani da waɗannan sababbin kayan ya inganta haɓaka fasahar sararin samaniya.

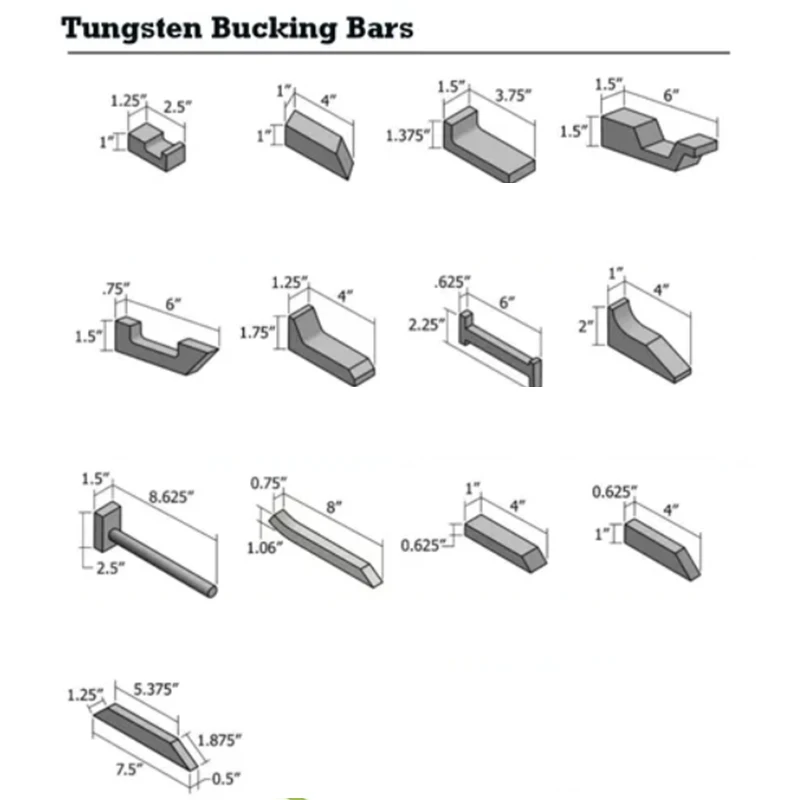

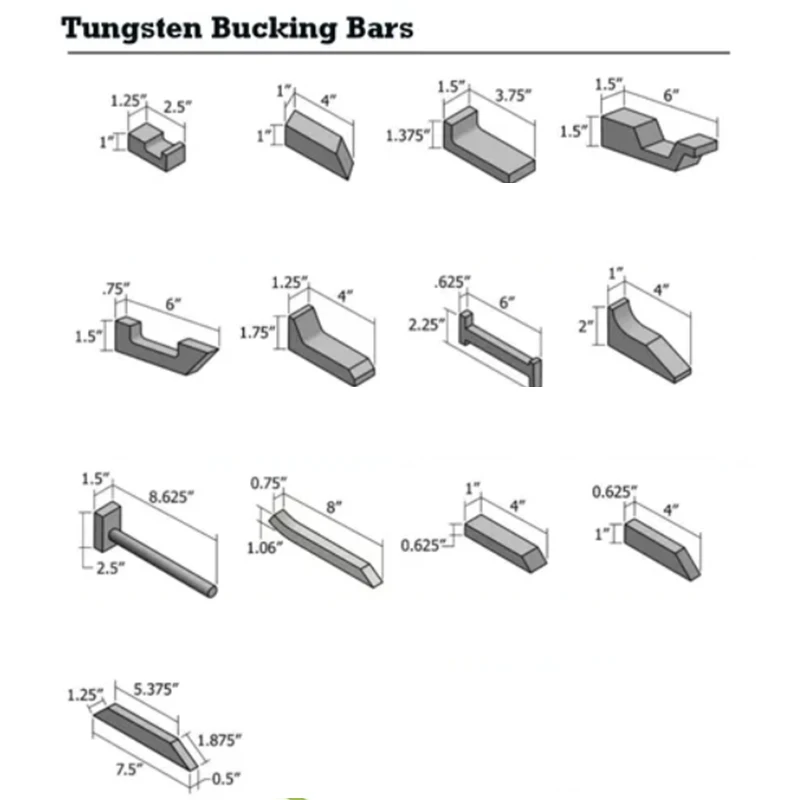

Menene Tungsten Bucking Bar?

Tungsten Bucsarki mashaya kayan aiki ne da aka karɓa a bayan saman aikin don samar da memba mai goyan baya a cikin amfani da na'urori masu tasiri tare da haɗawa da kai tsaye kayan aiki da sarrafa sassa tare da mai ɗaukar hoto mai ƙaranci mai ɗaukar tasiri idan aka bayar a can betwe.en don ɗaukar nauyin girgiza a cikin matsawa da ƙarfi.

Bucking Bars suna da fa'idodi masu zuwa idan aka kwatanta da sauran kayan aikin haɗin gwiwa

Amfani:

1. Babban ƙarfin haɗin gwiwa da aminci:

A lokacin aiwatar da riveting, Bucking Bars suna ba da tallafi mai ƙarfi da ƙarfi a bayan rivet, wanda zai iya lalata rivet ɗin daidai kuma ya samar da haɗi mai ƙarfi. Wannan hanyar haɗin kai na iya jure manyan lodi kamar tashin hankali, matsa lamba da ƙarfi. Idan aka kwatanta da wasu haɗin haɗin manne ko haɗin haɗin ferrule mai sauƙi, ƙarfin haɗinsa da amincinsa sun fi kyau, kuma ya dace da sifofi tare da buƙatun ƙarfin haɗin gwiwa, kamar fuselages na jirgin sama, gadoji, firam ɗin gini, da sauransu.

Ƙarƙashin amfani na dogon lokaci ko hadaddun yanayin aiki kamar rawar jiki da canje-canje na damuwa, tsarin da aka haɗa ta Bucking Bars na iya ci gaba da samun kwanciyar hankali mai kyau kuma baya yuwuwa ga sassautawa ko gazawar haɗin gwiwa.

Faɗin aiki:

2. Strong abu adaptability: Bucking Bars na daban-daban kayan za a iya zaba bisa ga daban-daban aiki bukatar daidaita da riveting na daban-daban kayan.

3. Ya dace da hadaddun sifofi: Za a iya tsara siffarsa da girmansa kuma a keɓance shi bisa ƙayyadaddun yanayin aiki, kuma ana iya sarrafa shi a cikin sifofi masu sarƙaƙƙiya da kunkuntar wurare, kamar bututu masu lanƙwasa, kunkuntar cavities, sifofi na musamman, da dai sauransu. ., wanda ke da wahala ga sauran kayan aikin haɗin kai da yawa suyi.

4. Mai sauƙin sarrafawa: Ana amfani da Bars na Bucking tare da kayan aiki irin su rivet bindigogi, kuma tsarin aiki yana da sauƙi.

Takamaiman lokuta na aikace-aikacen Bucking Bars a fagage daban-daban

1. Jirgin sama

Taron fuselage na jirgin sama: A lokacin aikin kera jirgin sama, ana buƙatar babban adadin riveting tsakanin fatar fuselage da firam. Misali, a cikin fuselage taron jiragen fasinja kamar Boeing 737 da Airbus A320, ana amfani da Bucking Bars don tabbatar da cewa rivets sun haɗa fata da firam.

Haɗin bangaren injin: Injin jirgin shi ne ainihin abin da ke cikin jirgin, kuma wasu abubuwa masu zafi da kuma tsarin da ke cikinsa su ma suna buƙatar haɗa su ta hanyar rive. Misali, ana iya kammala haɗin kai tsakanin injin injin injin da cibiyar tawul ta hanyar amfani da Bars Bucking. Shigar da rivets yana ba da damar yin amfani da ruwa don daidaitawa a kan tashar motar.

2. Filin kera motoci

Jiki firam taro: A cikin ƙera firam ɗin jikin mota, zanen ƙarfe na sifofi daban-daban da kauri yana buƙatar a haɗa su tare. Misali, a cikin tsarin hada firam ɗin motar, ana amfani da Bucking Bars don haɗa abubuwan haɗin gwiwa kamar katako na gefe, katakon giciye da firam ɗin rufin. Haɗin da aka ƙera zai iya ba da isasshen ƙarfi don jure jurewa da ƙarfin tasiri yayin tuƙin abin hawa. A lokaci guda, idan aka kwatanta da walda, riveting na iya rage nakasar jiki da inganta daidaiton taro na jiki.

Shigar kujerar mota: Hakanan ana amfani da riveting don gyara kujerun mota. Ana amfani da sandunan bucking ɗin don shigar da rivets ɗin wurin zama ta yadda kujerun za su iya jure ƙarfin da ba za a iya amfani da su ba ta hanyar birki kwatsam, juyi mai kaifi, da sauransu, don tabbatar da cewa kujerun ba za su sassauta ba.

3. Filin ginin jirgi

Hull harsashi splicing: A cikin ginin jirgin ruwa, harsashin ƙwanƙwasa yana raguwa da faranti da yawa na ƙarfe. Misali, a aikin kera jiragen dakon kaya mai nauyin ton 10,000, ana amfani da Bucking Bars wajen hada faranti na karfe ta hanyar rive. Tunda jiragen ruwa suna fama da abubuwa daban-daban kamar lalata ruwan teku, tasirin igiyar ruwa da matsa lamba a lokacin kewayawa, wannan hanyar riveting na iya tabbatar da hatimi da ƙarfin tsarin ginin da kuma hana ruwan teku shiga cikin kwanto.

Ginin tsarin cikin jirgi na ciki: Wasu manyan kantunan ɓangarorin da bene na tallafi a cikin jirgin kuma ana gina su ta hanyar riveting. Bucking Bars na iya taimakawa wajen kammala shigar da rivets a cikin gina waɗannan hadaddun sifofi na ciki, yin tsarin cikin gida na kamfanin jirgin da abin dogaro, yana ba da kariya ga amintaccen kewayawa na jirgin da ajiyar kaya.

4. Filin gini

Ƙarfe tsarin haɗin ginin: A cikin gine-ginen tsarin ƙarfe, irin su firam ɗin gina manyan wuraren motsa jiki, dakunan nunin da sauran gine-gine, ana amfani da Bars na Bucking don haɗa abubuwan haɗin ginin kamar katako na ƙarfe da ginshiƙan ƙarfe. Alal misali, a lokacin da ake gina karfe tsarin frame na National Stadium "Bird's Nest", an yi amfani da Bucking Bars don wasu rivet sadarwa. Wannan hanyar haɗin kai na iya tabbatar da kwanciyar hankali da amincin gine-ginen tsarin ƙarfe a ƙarƙashin yanayin nauyin nasu, nauyin iska, sojojin girgizar ƙasa, da dai sauransu.

Shigar bangon labule: Shigar da bangon labulen ginin wani lokaci ana yin ta ta hanyar rive. Bucking Bars na iya taimakawa wajen haɗa firam ɗin ƙarfe ko farantin bangon labule zuwa babban tsarin ginin, tabbatar da cewa bangon labulen zai iya zama karko a ƙarƙashin yanayi daban-daban (kamar iska mai ƙarfi, ruwan sama mai ƙarfi, da sauransu), da kuma yana da kyau rufewa don hana ruwan sama da shigar iska.

5. Filin samar da kayan aikin lantarki

Chassis harsashi taro: A cikin kera kayan aikin lantarki, irin su uwar garken chassis, chassis na kwamfuta, da sauransu, ana amfani da Bucking Bars don haɗa abubuwan haɗin harsashi na chassis. Waɗannan chassis suna buƙatar tabbatar da takamaiman aikin kariya na lantarki da ƙarfin injina. Riveting na iya sa harsashi ya haɗa ta sosai don saduwa da buƙatun garkuwar lantarki, kuma a lokaci guda yana iya jure wasu karo da extrusions don kare abubuwan lantarki na ciki.

Gyaran rediyo: Radiator na kayan aikin lantarki yawanci yana buƙatar daidaitawa akan guntu ko wasu abubuwan dumama. A cikin wasu manyan sabar ko kwamfutoci masu sarrafa masana'antu, ana amfani da Bucking Bars don shigar da rivet don gyara radiator don tabbatar da kyakkyawar hulɗa tsakanin radiator da kayan dumama, ta yadda zai iya watsar da zafi yadda ya kamata tare da hana kayan aikin lalacewa saboda yawan zafi.

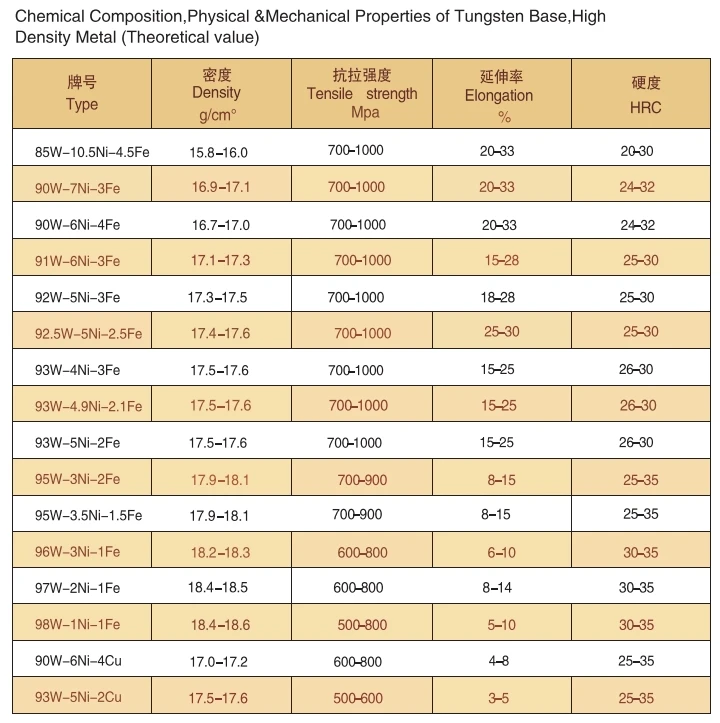

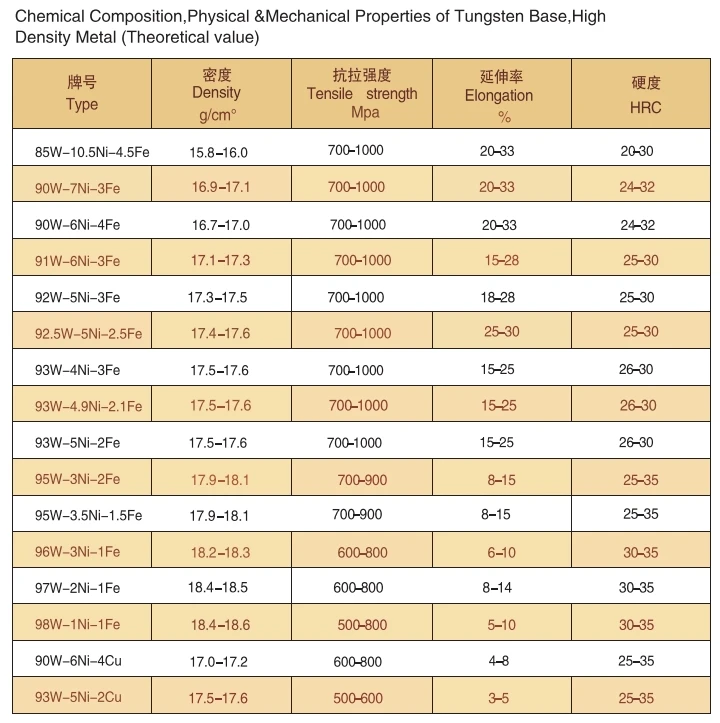

A taƙaice, WNiFe tungsten alloy bucking bar yana taka muhimmiyar rawa a fagage da yawa. Lokacin zabar mashaya bucking, dole ne ku zaɓi matakin abu mai dacewa bisa ga takamaiman buƙatun amfani da yanayin aiki don tabbatar da aikin sa da rayuwar sabis.

Abubuwan Ayyukanmu